Slip form pavers are an essential part of the road construction industry, responsible for laying down concrete slabs for roads, highways, and airport runways. Mastering slip form paver operations is crucial for achieving high-quality results, reducing costs, and increasing efficiency. In this article, we will explore five ways to master slip form paver operations and provide you with practical tips and insights to improve your skills.

Understanding the Basics of Slip Form Paving

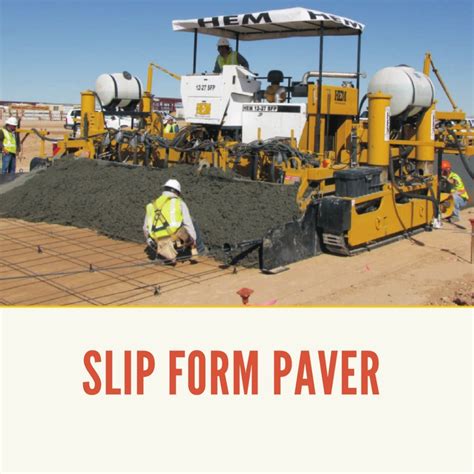

Before we dive into the five ways to master slip form paver operations, it's essential to understand the basics of slip form paving. Slip form paving is a process where concrete is poured into a mold, and a paving machine lays it down in a continuous slab. The process involves several key components, including the paver, the mold, the concrete mix, and the finishing crew.

To master slip form paver operations, you need to have a solid understanding of the equipment, materials, and processes involved. This includes knowledge of the paver's specifications, the concrete mix design, and the finishing techniques required to achieve a smooth, even surface.

Way 1: Optimize Paver Settings and Maintenance

Optimizing paver settings and maintenance is critical to achieving high-quality results and reducing downtime. Here are some tips to help you optimize your paver settings and maintenance:

- Check and adjust the paver's settings regularly to ensure it's operating within the manufacturer's specifications.

- Perform regular maintenance tasks, such as cleaning and lubricating the paver's components, to prevent wear and tear.

- Use the correct concrete mix design for the job, and ensure it's mixed and delivered correctly to the paver.

- Monitor the paver's performance regularly, and make adjustments as needed to maintain optimal performance.

By optimizing your paver settings and maintenance, you can improve the quality of your concrete slabs, reduce downtime, and increase efficiency.

Tips for Paver Maintenance:

- Check the paver's hydraulic system regularly for leaks and damage.

- Use a lubricant specifically designed for slip form pavers to prevent corrosion and wear.

- Clean the paver's mold and components regularly to prevent concrete buildup and damage.

Way 2: Improve Concrete Mix Design and Delivery

Improving concrete mix design and delivery is critical to achieving high-quality results and reducing defects. Here are some tips to help you improve your concrete mix design and delivery:

- Use a concrete mix design that's specifically designed for slip form paving, and ensure it meets the job's specifications.

- Monitor the concrete mix's temperature, slump, and air content regularly to ensure it's within the acceptable range.

- Use a concrete delivery system that's designed for slip form paving, and ensure it's properly maintained and calibrated.

- Train your finishing crew on the importance of proper concrete finishing techniques, including leveling, smoothing, and texturing.

By improving your concrete mix design and delivery, you can improve the quality of your concrete slabs, reduce defects, and increase efficiency.

Tips for Concrete Mix Design:

- Use a concrete mix design that's specifically designed for slip form paving, and ensure it meets the job's specifications.

- Monitor the concrete mix's temperature, slump, and air content regularly to ensure it's within the acceptable range.

- Use a concrete delivery system that's designed for slip form paving, and ensure it's properly maintained and calibrated.

Way 3: Enhance Finishing Techniques and Training

Enhancing finishing techniques and training is critical to achieving high-quality results and reducing defects. Here are some tips to help you enhance your finishing techniques and training:

- Train your finishing crew on the importance of proper concrete finishing techniques, including leveling, smoothing, and texturing.

- Use a finishing crew that's experienced in slip form paving, and ensure they're properly trained and equipped.

- Monitor the finishing crew's performance regularly, and provide feedback and training as needed.

- Use a quality control process to ensure the finished concrete meets the job's specifications.

By enhancing your finishing techniques and training, you can improve the quality of your concrete slabs, reduce defects, and increase efficiency.

Tips for Finishing Techniques:

- Use a leveling system to ensure the concrete is properly leveled and smoothed.

- Use a texturing system to create a uniform texture and pattern.

- Train your finishing crew on the importance of proper concrete finishing techniques, including leveling, smoothing, and texturing.

Way 4: Implement Quality Control Processes

Implementing quality control processes is critical to achieving high-quality results and reducing defects. Here are some tips to help you implement quality control processes:

- Use a quality control process to ensure the finished concrete meets the job's specifications.

- Monitor the paver's performance regularly, and make adjustments as needed to maintain optimal performance.

- Use a concrete testing laboratory to test the concrete's strength, durability, and other properties.

- Train your quality control team on the importance of proper quality control techniques, including testing and inspection.

By implementing quality control processes, you can improve the quality of your concrete slabs, reduce defects, and increase efficiency.

Tips for Quality Control:

- Use a quality control process to ensure the finished concrete meets the job's specifications.

- Monitor the paver's performance regularly, and make adjustments as needed to maintain optimal performance.

- Use a concrete testing laboratory to test the concrete's strength, durability, and other properties.

Way 5: Leverage Technology and Innovation

Leveraging technology and innovation is critical to achieving high-quality results and reducing costs. Here are some tips to help you leverage technology and innovation:

- Use a paver that's equipped with advanced technology, including GPS, sensors, and automation systems.

- Use a concrete mix design that's optimized for slip form paving, and ensure it's mixed and delivered correctly to the paver.

- Use a quality control process that's integrated with the paver's systems, and ensures the finished concrete meets the job's specifications.

- Train your team on the importance of proper technology and innovation techniques, including GPS, sensors, and automation systems.

By leveraging technology and innovation, you can improve the quality of your concrete slabs, reduce costs, and increase efficiency.

Tips for Technology and Innovation:

- Use a paver that's equipped with advanced technology, including GPS, sensors, and automation systems.

- Use a concrete mix design that's optimized for slip form paving, and ensure it's mixed and delivered correctly to the paver.

- Use a quality control process that's integrated with the paver's systems, and ensures the finished concrete meets the job's specifications.

As you can see, mastering slip form paver operations requires a combination of technical knowledge, practical experience, and innovative thinking. By following these five ways to master slip form paver operations, you can improve the quality of your concrete slabs, reduce costs, and increase efficiency.

We hope this article has provided you with valuable insights and practical tips to improve your slip form paver operations. Whether you're a seasoned contractor or a newcomer to the industry, we encourage you to share your thoughts and experiences in the comments below.

What is slip form paving?

+Slip form paving is a process where concrete is poured into a mold, and a paving machine lays it down in a continuous slab.

What are the benefits of slip form paving?

+The benefits of slip form paving include improved quality, reduced costs, and increased efficiency.

How do I optimize my paver settings and maintenance?

+Optimizing your paver settings and maintenance involves checking and adjusting the paver's settings regularly, performing regular maintenance tasks, and using the correct concrete mix design for the job.