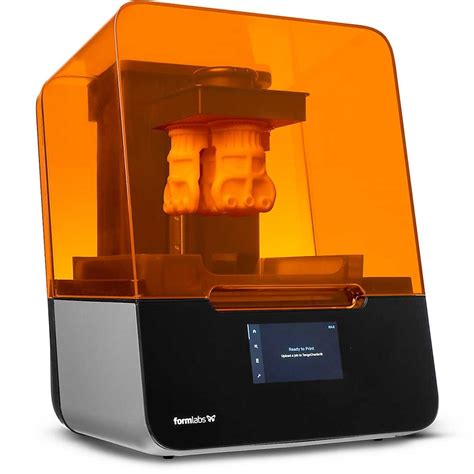

Mastering the Formlabs Form 3+ 3D printer requires a combination of technical knowledge, practical experience, and attention to detail. With its advanced features and capabilities, the Form 3+ is a powerful tool for creating complex prints with high accuracy and precision. However, getting the most out of this printer requires a deep understanding of its operation, capabilities, and limitations.

Whether you're a seasoned 3D printing professional or just starting out, mastering the Formlabs Form 3+ can take your printing capabilities to the next level. In this article, we'll explore five tips for getting the most out of your Form 3+ printer, from optimizing print settings to troubleshooting common issues.

Understanding the Form 3+ Printer

Before we dive into the tips, it's essential to understand the basics of the Form 3+ printer. The Form 3+ is a stereolithography (SLA) 3D printer that uses a laser to cure liquid resin, layer by layer, to create highly detailed and accurate prints. The printer features a compact design, a large build volume, and advanced features like automatic resin dispensing and temperature control.

Tip 1: Optimizing Print Settings

Optimizing print settings is crucial for getting the best results from your Form 3+ printer. The printer comes with a range of pre-configured print settings, but you may need to adjust these settings to suit your specific printing needs.

- Layer Thickness: Adjusting the layer thickness can affect the print's resolution, speed, and material usage. Thicker layers can reduce print time but may compromise on resolution, while thinner layers can improve resolution but increase print time.

- Exposure Time: The exposure time controls how long the laser is applied to each layer. Adjusting this setting can affect the print's accuracy and material curing.

- Resin Temperature: The resin temperature affects the print's curing and flow. Adjusting this setting can improve print quality and reduce the risk of defects.

Advanced Print Settings

In addition to the basic print settings, the Form 3+ also offers advanced settings that can further optimize your prints. These include:

- Support Generation: The Form 3+ allows you to generate custom supports for your prints. This can be useful for complex prints that require additional support structures.

- Infill Density: Adjusting the infill density can affect the print's weight, strength, and material usage. Higher infill densities can improve the print's strength but increase material usage.

- Surface Finish: The Form 3+ allows you to adjust the surface finish of your prints. This can be useful for creating prints with specific textures or finishes.

Tip 2: Using the Right Resin

The Form 3+ is compatible with a range of Formlabs resins, each with its own unique properties and characteristics. Choosing the right resin for your print can affect the print's quality, durability, and appearance.

- Clear Resin: Clear resin is ideal for creating transparent or translucent prints. It's often used for printing prototypes, models, and display pieces.

- White Resin: White resin is a general-purpose resin that's suitable for most printing applications. It's often used for printing prototypes, models, and production parts.

- Flexible Resin: Flexible resin is a flexible and elastic material that's ideal for creating prints that require flexibility and durability. It's often used for printing prototypes, models, and production parts.

Resin Properties

Understanding the properties of each resin can help you choose the right material for your print. Here are some key properties to consider:

- Viscosity: The viscosity of the resin affects its flow and curing. Thicker resins can be more difficult to print with, while thinner resins can be more prone to defects.

- Curing Time: The curing time affects how long the resin takes to cure. Faster curing times can improve print speed, while slower curing times can improve print quality.

- Tensile Strength: The tensile strength affects the print's durability and resistance to stress. Higher tensile strengths can improve the print's durability, while lower tensile strengths can compromise on durability.

Tip 3: Maintaining the Printer

Regular maintenance is crucial for keeping your Form 3+ printer in good working order. Here are some tips for maintaining your printer:

- Clean the Printer: Regularly clean the printer's exterior and interior to prevent dust and debris from accumulating.

- Check the Laser: Check the laser's alignment and focus regularly to ensure accurate prints.

- Replace the Resin Tank: Replace the resin tank regularly to prevent contamination and ensure optimal print quality.

Printer Maintenance Schedule

Creating a maintenance schedule can help you stay on top of printer maintenance. Here's a sample schedule:

- Daily: Clean the printer's exterior and interior, check the laser's alignment and focus, and replace the resin tank.

- Weekly: Check the printer's firmware and update it if necessary, clean the printer's fans and air filters, and inspect the printer's cables and connectors.

- Monthly: Perform a deep clean of the printer, including the resin tank and laser, and replace the printer's consumables.

Tip 4: Troubleshooting Common Issues

Even with regular maintenance, issues can still arise. Here are some common issues and troubleshooting tips:

- Print Failure: Check the print settings, resin level, and laser alignment. Ensure the printer is properly calibrated and the resin tank is not empty.

- Resin Leaks: Check the resin tank's seals and connections. Ensure the resin tank is properly secured and the printer's fans are working correctly.

- Laser Issues: Check the laser's alignment and focus. Ensure the laser is properly calibrated and the printer's optics are clean.

Troubleshooting Guide

Creating a troubleshooting guide can help you quickly identify and resolve common issues. Here's a sample guide:

- Print Failure:

- Check print settings

- Check resin level

- Check laser alignment

- Resin Leaks:

- Check resin tank seals and connections

- Check resin tank security

- Check printer's fans and air filters

- Laser Issues:

- Check laser alignment and focus

- Check laser calibration

- Check printer's optics and mirrors

Tip 5: Upgrading the Printer

The Form 3+ is a highly upgradeable printer, and upgrading can improve its performance and capabilities. Here are some upgrade options:

- Firmware Upgrades: Regularly update the printer's firmware to access new features and improvements.

- Hardware Upgrades: Upgrade the printer's hardware, such as the resin tank or laser, to improve performance and capabilities.

- Accessory Upgrades: Upgrade the printer's accessories, such as the build platform or supports, to improve print quality and ease of use.

Upgrading the Form 3+

Upgrading the Form 3+ can be a cost-effective way to improve its performance and capabilities. Here are some upgrade options:

- Firmware Upgrade: Update the printer's firmware to access new features and improvements.

- Resin Tank Upgrade: Upgrade the resin tank to improve print quality and reduce material waste.

- Laser Upgrade: Upgrade the laser to improve print speed and accuracy.

By following these tips, you can master the Formlabs Form 3+ 3D printer and unlock its full potential. Remember to optimize print settings, use the right resin, maintain the printer, troubleshoot common issues, and upgrade the printer to improve its performance and capabilities.

We hope you found this article helpful! If you have any questions or comments, please leave them below. Don't forget to share this article with your friends and colleagues who might be interested in mastering the Formlabs Form 3+.

What is the Formlabs Form 3+?

+The Formlabs Form 3+ is a stereolithography (SLA) 3D printer that uses a laser to cure liquid resin, layer by layer, to create highly detailed and accurate prints.

What are the benefits of using the Formlabs Form 3+?

+The Formlabs Form 3+ offers a range of benefits, including high accuracy and precision, fast print speeds, and a large build volume. It's also highly upgradeable and customizable.