As the seasons change and the weather gets colder, many industries start to transition into their winter modes of operation. For those working at heights, fall protection equipment becomes an essential aspect of daily operations. However, without regular inspections, this equipment can become a liability rather than a safety asset. That's why it's crucial to have a fall protection inspection form in place, and in this article, we'll explore the 7 essential items to include in your Excel template.

Understanding the Importance of Fall Protection Inspection

Before we dive into the essential items for your fall protection inspection form, it's crucial to understand why these inspections are necessary. According to the Occupational Safety and Health Administration (OSHA), falls are one of the leading causes of workplace injuries and fatalities. In 2020, falls accounted for 351 fatalities out of 1,061 total fatalities in the construction industry alone.

Regular inspections of fall protection equipment can help identify potential hazards and prevent accidents. By incorporating these inspections into your maintenance routine, you can ensure that your equipment is in good working condition and your employees are safe while working at heights.

Benefits of Using an Excel Template for Fall Protection Inspection

Using an Excel template for your fall protection inspection form offers several benefits. For one, it allows you to create a standardized inspection process that can be easily repeated and tracked. Additionally, an Excel template can help you:

- Streamline your inspection process

- Improve data collection and analysis

- Increase efficiency and reduce inspection time

- Enhance compliance with regulatory requirements

7 Essential Items for Fall Protection Inspection Form in Excel

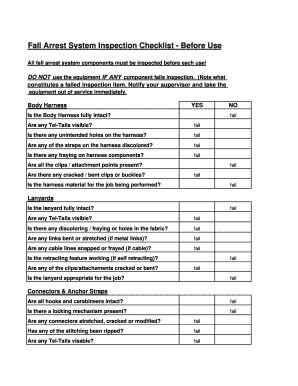

When creating your fall protection inspection form in Excel, there are 7 essential items you should include:

1. Equipment Information

- Equipment ID or serial number

- Type of equipment (e.g., harness, lanyard, anchor point)

- Date of manufacture

- Date of last inspection

2. Visual Inspection

- Check for signs of wear, damage, or deterioration

- Inspect for proper labeling and marking

- Verify that all components are securely attached

3. Functional Testing

- Test the equipment's functionality and performance

- Verify that all components are working correctly

- Check for any signs of malfunction or failure

4. Anchorage Point Inspection

- Verify that the anchorage point is securely attached to the structure

- Check for any signs of wear or damage

- Ensure that the anchorage point is rated for the intended use

5. Connectors and Lanyards

- Inspect for signs of wear, damage, or deterioration

- Verify that all connectors and lanyards are properly attached

- Check for any signs of malfunction or failure

6. Harness and Body Wear Inspection

- Inspect for signs of wear, damage, or deterioration

- Verify that all harness and body wear components are properly attached

- Check for any signs of malfunction or failure

7. Certification and Compliance

- Verify that the equipment meets regulatory requirements (e.g., OSHA, ANSI)

- Check for any certifications or compliance markings

- Ensure that the equipment is properly documented and recorded

Best Practices for Conducting Fall Protection Inspections

When conducting fall protection inspections, it's essential to follow best practices to ensure accuracy and effectiveness. Here are some tips to keep in mind:

- Always follow the manufacturer's instructions for inspection and maintenance

- Use a standardized inspection checklist to ensure consistency

- Take photos and document any damage or issues found during the inspection

- Ensure that all inspections are conducted by a competent person

Creating a Fall Protection Inspection Form in Excel

Creating a fall protection inspection form in Excel is a straightforward process. Here's a step-by-step guide to get you started:

- Open a new Excel spreadsheet and create a table with the essential items listed above.

- Add columns for the inspector's name, date of inspection, and any additional notes or comments.

- Use conditional formatting to highlight any issues or defects found during the inspection.

- Use formulas to calculate the inspection results and generate a summary report.

- Save the template and use it for future inspections.

Conclusion

In conclusion, fall protection inspections are a critical aspect of maintaining a safe working environment. By incorporating the 7 essential items into your Excel template, you can ensure that your equipment is in good working condition and your employees are safe while working at heights. Remember to follow best practices and use a standardized inspection checklist to ensure accuracy and effectiveness.

We hope you found this article informative and helpful. Don't forget to share your thoughts and experiences with fall protection inspections in the comments below. If you have any questions or need further assistance, feel free to ask.

What is the purpose of a fall protection inspection?

+The purpose of a fall protection inspection is to identify potential hazards and prevent accidents by ensuring that fall protection equipment is in good working condition.

How often should fall protection equipment be inspected?

+Fall protection equipment should be inspected regularly, ideally before each use, and at least once a year by a competent person.

Who is responsible for conducting fall protection inspections?

+The responsibility for conducting fall protection inspections lies with the employer or site manager, who should designate a competent person to perform the inspections.