The Occupational Safety and Health Administration (OSHA) requires crane operators to perform daily inspections to ensure the safe operation of cranes and prevent accidents. A daily crane inspection form is a critical tool in this process, providing a comprehensive checklist to help operators identify potential hazards and take corrective action. In this article, we will delve into the importance of daily crane inspections, the key components of an OSHA daily crane inspection form, and provide a sample checklist to help operators ensure compliance.

Importance of Daily Crane Inspections

Daily crane inspections are crucial in preventing accidents and ensuring the safe operation of cranes. According to OSHA, crane accidents often result from inadequate maintenance, operator error, and failure to follow safety procedures. A daily inspection can help identify potential hazards, such as worn or damaged components, hydraulic leaks, and electrical issues, allowing operators to take corrective action before an accident occurs.

Key Components of an OSHA Daily Crane Inspection Form

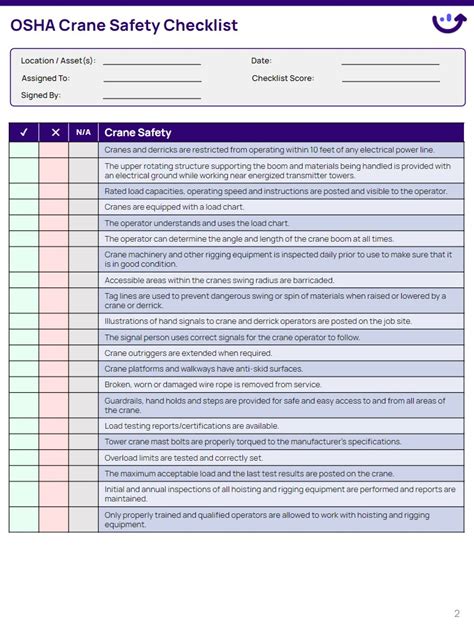

An OSHA daily crane inspection form should include the following key components:

- Crane identification: The form should include the crane's make, model, and serial number.

- Date and time: The date and time of the inspection should be recorded.

- Inspector's signature: The inspector's signature should be included to verify that the inspection was performed.

- Checklist: A comprehensive checklist of items to inspect, including:

- Boom and boom sections

- Hoist ropes and wire ropes

- Hooks and latches

- Hydraulic systems

- Electrical systems

- Control systems

- Safety devices (e.g., load moment indicators, anti-two-block devices)

- Condition of components: The form should include space to record the condition of each component, including any damage or wear.

- Action required: The form should include space to record any action required to address deficiencies or hazards identified during the inspection.

Sample OSHA Daily Crane Inspection Checklist

Here is a sample OSHA daily crane inspection checklist:

- Boom and boom sections:

- Inspect for damage, wear, or corrosion.

- Check for proper alignment and securement.

- Hoist ropes and wire ropes:

- Inspect for damage, wear, or corrosion.

- Check for proper tension and securement.

- Hooks and latches:

- Inspect for damage, wear, or corrosion.

- Check for proper securement and alignment.

- Hydraulic systems:

- Inspect for leaks or damage.

- Check hydraulic fluid levels and condition.

- Electrical systems:

- Inspect for damage or wear.

- Check for proper connections and securement.

- Control systems:

- Inspect for damage or wear.

- Check for proper function and response.

- Safety devices:

- Inspect for damage or wear.

- Check for proper function and response.

Benefits of Using an OSHA Daily Crane Inspection Form

Using an OSHA daily crane inspection form provides several benefits, including:

- Improved safety: By identifying potential hazards and taking corrective action, operators can reduce the risk of accidents and improve safety.

- Increased productivity: By ensuring that cranes are properly maintained and functioning correctly, operators can reduce downtime and increase productivity.

- Compliance with regulations: Using an OSHA daily crane inspection form helps operators comply with OSHA regulations and avoid fines and penalties.

- Reduced maintenance costs: By identifying and addressing potential issues early, operators can reduce maintenance costs and extend the life of the crane.

Best Practices for Conducting Daily Crane Inspections

To ensure that daily crane inspections are effective, operators should follow these best practices:

- Use a comprehensive checklist: Use a checklist that includes all components of the crane, including boom and boom sections, hoist ropes and wire ropes, hooks and latches, hydraulic systems, electrical systems, control systems, and safety devices.

- Conduct inspections regularly: Conduct inspections daily, or as required by OSHA regulations.

- Take corrective action: Take corrective action to address any deficiencies or hazards identified during the inspection.

- Maintain records: Maintain records of inspections, including the date and time of the inspection, the inspector's signature, and any action required.

By following these best practices and using an OSHA daily crane inspection form, operators can ensure that their cranes are safe, productive, and compliant with regulations.

We hope this article has been informative and helpful in understanding the importance of daily crane inspections and the key components of an OSHA daily crane inspection form. If you have any questions or comments, please feel free to share them below.

What is the purpose of a daily crane inspection?

+The purpose of a daily crane inspection is to identify potential hazards and take corrective action to ensure the safe operation of the crane.

What are the key components of an OSHA daily crane inspection form?

+The key components of an OSHA daily crane inspection form include crane identification, date and time, inspector's signature, checklist, condition of components, and action required.

What are the benefits of using an OSHA daily crane inspection form?

+The benefits of using an OSHA daily crane inspection form include improved safety, increased productivity, compliance with regulations, and reduced maintenance costs.