Understanding the Importance of Respirator Fit Testing

Respirators are an essential part of personal protective equipment (PPE) in various industries, including healthcare, construction, and manufacturing. They help protect workers from airborne contaminants, such as dust, fumes, and chemicals. However, respirators only provide the desired level of protection if they fit properly. That's where respirator fit testing comes in – a crucial process that ensures the respirator is correctly fitted to the wearer's face.

The Risks of Poorly Fitted Respirators

A poorly fitted respirator can lead to serious health consequences, including respiratory problems, cancer, and even death. When a respirator doesn't fit correctly, it can allow contaminated air to enter the mask, compromising the wearer's safety. This is especially concerning in high-risk industries where workers are exposed to hazardous materials.

What is Respirator Fit Testing?

Respirator fit testing is a process that evaluates the fit of a respirator on an individual's face. The test assesses the seal between the respirator and the wearer's skin, ensuring that the mask is able to filter out airborne contaminants effectively. There are two main types of respirator fit testing: qualitative and quantitative.

Qualitative Fit Testing (QLFT)

QLFT is a pass/fail test that uses a taste or odor detection method to assess the fit of a respirator. During the test, the wearer is exposed to a sweet or bitter taste or a strong odor, and they are asked to indicate if they can detect it. If the wearer can taste or smell the substance, it indicates that the respirator is not fitting properly.

Quantitative Fit Testing (QNFT)

QNFT is a more advanced test that uses a device to measure the actual amount of leakage around the respirator. This test provides a numerical fit factor, which indicates the level of protection provided by the respirator.

Why is Respirator Fit Testing Important?

Respirator fit testing is essential for several reasons:

- Ensures worker safety: Respirator fit testing helps ensure that workers are protected from airborne contaminants, reducing the risk of respiratory problems and other health issues.

- Compliance with regulations: OSHA requires respirator fit testing for workers who wear respirators in certain industries.

- Prevents costly errors: A poorly fitted respirator can lead to costly errors, such as contaminated products or equipment damage.

- Boosts productivity: When workers feel confident in their respirator's fit, they are more likely to be productive and focused on their work.

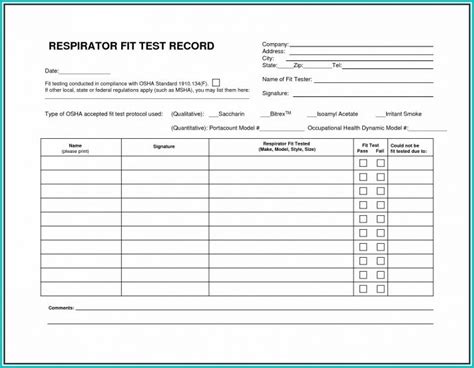

Free Printable Respirator Fit Test Form Template

To help you conduct respirator fit testing efficiently, we've created a free printable respirator fit test form template. This template includes the following sections:

- Worker information: Name, job title, and department

- Respirator information: Type, size, and manufacturer

- Fit test results: Pass/fail indication, fit factor (for QNFT), and any notes or comments

- Test administrator information: Name, title, and signature

You can download and print this template to use during your respirator fit testing procedures.

How to Conduct a Respirator Fit Test

Conducting a respirator fit test involves the following steps:

- Prepare the testing area: Ensure the testing area is clean, dry, and free from airborne contaminants.

- Select the respirator: Choose the respirator to be tested, and ensure it is in good condition.

- Prepare the worker: Instruct the worker to remove any facial hair, glasses, or other items that may interfere with the test.

- Conduct the test: Perform the fit test according to the manufacturer's instructions and OSHA guidelines.

- Record the results: Use the respirator fit test form template to record the results, including any notes or comments.

Best Practices for Respirator Fit Testing

To ensure accurate and reliable respirator fit testing, follow these best practices:

- Use a qualified test administrator: Ensure the test administrator is trained and experienced in conducting respirator fit testing.

- Use the correct testing equipment: Use the manufacturer-recommended testing equipment and follow the instructions carefully.

- Test in a controlled environment: Conduct the test in a controlled environment, free from airborne contaminants and distractions.

- Retest regularly: Retest workers regularly, ideally every 12 months, or whenever there is a change in the worker's physical condition or the respirator.

Conclusion

Respirator fit testing is a critical process that ensures the safety and health of workers in various industries. By understanding the importance of respirator fit testing, using a free printable respirator fit test form template, and following best practices, you can help prevent respiratory problems and ensure a safe working environment.

If you have any questions or concerns about respirator fit testing, please don't hesitate to comment below. Share this article with your colleagues and friends to help spread awareness about the importance of respirator fit testing.

What is the purpose of respirator fit testing?

+Respirator fit testing ensures that the respirator is correctly fitted to the wearer's face, providing the desired level of protection from airborne contaminants.

What are the two main types of respirator fit testing?

+Qualitative fit testing (QLFT) and quantitative fit testing (QNFT) are the two main types of respirator fit testing.

How often should workers be retested?

+Workers should be retested every 12 months, or whenever there is a change in the worker's physical condition or the respirator.