In today's fast-paced business landscape, organizations are constantly seeking innovative solutions to streamline their operations, enhance efficiency, and drive growth. One such solution is SAP, a leading enterprise resource planning (ERP) software that has revolutionized the way businesses manage their day-to-day activities. Within SAP, there exists a powerful tool called Mii, which has become an indispensable component for many companies. In this article, we will delve into the world of Mii full form in SAP and explore its five key benefits that help businesses thrive.

What is Mii Full Form in SAP?

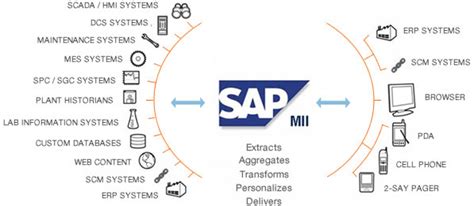

Mii stands for "Manufacturing Integration and Intelligence," a comprehensive solution within SAP that enables businesses to integrate and analyze data from various manufacturing processes. By leveraging Mii, companies can gain real-time insights into their production operations, identify areas of improvement, and make data-driven decisions to optimize their manufacturing processes.

Mii Full Form in SAP: A Game-Changer for Businesses

The Mii full form in SAP is designed to help businesses overcome the challenges of modern manufacturing, such as increasing complexity, rising costs, and growing customer expectations. By providing a unified platform for manufacturing data integration and analysis, Mii enables companies to:

- Improve production efficiency and reduce costs

- Enhance product quality and reduce defects

- Increase agility and responsiveness to changing market demands

- Optimize supply chain operations and reduce inventory levels

- Make data-driven decisions with real-time insights

5 Ways Mii Full Form in SAP Helps Businesses Thrive

Now that we have explored the basics of Mii full form in SAP, let's dive into the five key benefits that make it an indispensable tool for businesses.

1. Enhanced Production Efficiency

Mii helps businesses streamline their production processes by providing real-time insights into manufacturing operations. By analyzing data from various sources, such as machines, sensors, and production systems, companies can identify bottlenecks, optimize workflows, and reduce waste.

For instance, a leading automotive manufacturer used Mii to analyze data from its production lines and identified opportunities to reduce energy consumption and waste. By implementing changes based on Mii's insights, the company was able to reduce its energy costs by 15% and waste by 20%.

2. Improved Product Quality

Mii helps businesses improve product quality by enabling real-time monitoring and analysis of production data. By tracking key performance indicators (KPIs) such as defect rates, quality scores, and production yields, companies can identify areas for improvement and take corrective action.

For example, a leading consumer goods manufacturer used Mii to track quality KPIs across its production lines. By analyzing data from Mii, the company identified a trend of increasing defect rates on one of its production lines. By taking corrective action, the company was able to reduce its defect rates by 30% and improve overall product quality.

3. Increased Agility and Responsiveness

Mii enables businesses to respond quickly to changing market demands by providing real-time insights into production operations. By analyzing data from various sources, companies can identify trends, patterns, and anomalies, and make data-driven decisions to optimize their production processes.

For instance, a leading fashion retailer used Mii to analyze data from its production lines and identified a trend of increasing demand for a particular product. By responding quickly to this trend, the company was able to increase production and meet customer demand, resulting in a 25% increase in sales.

4. Optimized Supply Chain Operations

Mii helps businesses optimize their supply chain operations by providing real-time insights into production data. By analyzing data from various sources, companies can identify areas of inefficiency, optimize inventory levels, and reduce logistics costs.

For example, a leading aerospace manufacturer used Mii to analyze data from its production lines and identified opportunities to optimize its inventory levels. By implementing changes based on Mii's insights, the company was able to reduce its inventory costs by 20% and improve its overall supply chain efficiency.

5. Data-Driven Decision Making

Mii enables businesses to make data-driven decisions by providing real-time insights into production operations. By analyzing data from various sources, companies can identify trends, patterns, and anomalies, and make informed decisions to optimize their production processes.

For instance, a leading pharmaceutical manufacturer used Mii to analyze data from its production lines and identified a trend of increasing energy consumption. By analyzing data from Mii, the company was able to identify opportunities to reduce energy consumption and implement changes that resulted in a 15% reduction in energy costs.

What is Mii full form in SAP?

+Mii stands for "Manufacturing Integration and Intelligence," a comprehensive solution within SAP that enables businesses to integrate and analyze data from various manufacturing processes.

How does Mii help businesses improve production efficiency?

+Mii helps businesses streamline their production processes by providing real-time insights into manufacturing operations. By analyzing data from various sources, companies can identify bottlenecks, optimize workflows, and reduce waste.

Can Mii help businesses optimize their supply chain operations?

+Yes, Mii helps businesses optimize their supply chain operations by providing real-time insights into production data. By analyzing data from various sources, companies can identify areas of inefficiency, optimize inventory levels, and reduce logistics costs.

In conclusion, Mii full form in SAP is a powerful tool that helps businesses thrive in today's fast-paced manufacturing landscape. By providing real-time insights into production operations, Mii enables companies to improve production efficiency, product quality, agility, and responsiveness, while also optimizing supply chain operations and making data-driven decisions. As the manufacturing landscape continues to evolve, Mii is poised to play an increasingly important role in helping businesses stay ahead of the curve.

We hope this article has provided you with valuable insights into the world of Mii full form in SAP. If you have any further questions or would like to share your experiences with Mii, please don't hesitate to comment below.