The importance of ladder safety in the workplace cannot be overstated. According to the Occupational Safety and Health Administration (OSHA), ladder-related accidents are a leading cause of workplace injuries and fatalities. In fact, the Bureau of Labor Statistics reports that over 300 workers die each year from ladder-related falls, and thousands more are injured. To mitigate this risk, OSHA requires employers to inspect ladders regularly to ensure they are in good working condition.

Why is Ladder Inspection Important?

Regular ladder inspection is crucial to preventing accidents and ensuring workplace safety. Ladders are often used in a variety of settings, including construction sites, warehouses, and office buildings. Over time, ladders can become worn and damaged, which can lead to catastrophic consequences if not addressed. By inspecting ladders regularly, employers can identify potential hazards and take corrective action before an accident occurs.

The Benefits of Ladder Inspection

There are numerous benefits to regular ladder inspection, including:

- Reduced risk of accidents and injuries

- Compliance with OSHA regulations

- Extended lifespan of ladders

- Increased productivity and efficiency

- Improved workplace morale and safety culture

OSHA Ladder Inspection Requirements

OSHA requires employers to inspect ladders regularly to ensure they are in good working condition. The frequency of inspections depends on the type of ladder and its usage. For example, ladders used in harsh environments or for heavy-duty applications may require more frequent inspections.

What to Look for During a Ladder Inspection

During a ladder inspection, employers should look for the following:

- Damage to the ladder's structure, including cracks, dents, and corrosion

- Wear and tear on rungs, steps, and feet

- Proper labeling and marking

- Secure footing and level ground

- Adequate weight capacity

How to Conduct a Ladder Inspection

Conducting a ladder inspection is a straightforward process that can be completed in a few steps. Here's a step-by-step guide:

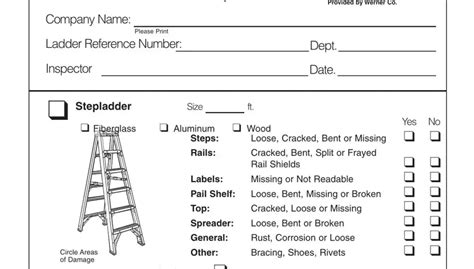

- Gather necessary equipment: Before starting the inspection, gather a ladder inspection checklist and a pen or pencil.

- Visual inspection: Begin by visually inspecting the ladder for any signs of damage or wear.

- Check for damage: Check the ladder's structure, rungs, steps, and feet for any signs of damage or wear.

- Check labeling and marking: Verify that the ladder is properly labeled and marked.

- Check footing and level ground: Ensure that the ladder is placed on secure footing and level ground.

- Check weight capacity: Verify that the ladder is rated for the intended use and weight capacity.

Ladder Inspection Checklist

Using a ladder inspection checklist can help ensure that all necessary items are inspected. Here's a sample checklist:

- Ladder structure:

- No cracks or damage

- No corrosion or rust

- No loose or missing rungs

- Rungs and steps:

- No damage or wear

- No slippery surfaces

- No missing or loose rungs

- Feet and footing:

- Secure and level ground

- No slipping or sliding

- No damage or wear

- Labeling and marking:

- Proper labeling and marking

- No missing or illegible labels

- Weight capacity:

- Rated for intended use

- No exceeding weight capacity

Ladder Inspection Frequency

The frequency of ladder inspections depends on the type of ladder and its usage. Here are some general guidelines:

- Daily inspections: Ladders used in harsh environments or for heavy-duty applications should be inspected daily.

- Weekly inspections: Ladders used in moderate environments or for light-duty applications should be inspected weekly.

- Monthly inspections: Ladders used in mild environments or for occasional use should be inspected monthly.

What to Do if a Ladder Fails Inspection

If a ladder fails inspection, it should be removed from service immediately. Here are some steps to take:

- Remove the ladder from service: Immediately remove the ladder from service to prevent any further use.

- Repair or replace the ladder: Repair or replace the ladder as needed.

- Reinspect the ladder: Reinspect the ladder to ensure it is safe for use.

Conclusion

Regular ladder inspection is crucial to preventing accidents and ensuring workplace safety. By following OSHA guidelines and using a ladder inspection checklist, employers can ensure that ladders are in good working condition and reduce the risk of accidents. Remember to inspect ladders regularly, and don't hesitate to remove a ladder from service if it fails inspection.

What is the purpose of a ladder inspection?

+The purpose of a ladder inspection is to ensure that ladders are in good working condition and safe for use.

How often should ladders be inspected?

+The frequency of ladder inspections depends on the type of ladder and its usage. Daily, weekly, or monthly inspections may be required.

What should be done if a ladder fails inspection?

+If a ladder fails inspection, it should be removed from service immediately. Repair or replace the ladder as needed, and reinspecting the ladder to ensure it is safe for use.