Inflatable forms have revolutionized various industries, including product design, architecture, and even aerospace engineering. However, one area where inflatable forms are making a significant impact is in the field of 3D form design. Specifically, Inflatable 3dfx forms are gaining popularity among designers and manufacturers due to their unique combination of flexibility, durability, and cost-effectiveness.

For decades, designers and engineers have relied on traditional materials like metal, wood, and plastic to create complex shapes and forms. However, these materials often come with limitations, such as high production costs, limited flexibility, and environmental concerns. Inflatable forms, on the other hand, offer a game-changing solution that can overcome these challenges.

What are Inflatable 3dfx Forms?

Inflatable 3dfx forms are a type of inflatable structure that can be designed and manufactured to create complex shapes and forms. These forms are typically made from flexible materials like silicone, rubber, or plastic, which can be inflated with air or gas to achieve the desired shape. Inflatable 3dfx forms can be used in various applications, including product design, architecture, and even medical devices.

Benefits of Inflatable 3dfx Forms

One of the primary benefits of inflatable 3dfx forms is their flexibility. Unlike traditional materials, inflatable forms can be easily deflated and stored, making them ideal for applications where space is limited. Additionally, inflatable forms can be designed to be highly durable and resistant to damage, making them suitable for use in harsh environments.

Another significant advantage of inflatable 3dfx forms is their cost-effectiveness. Compared to traditional materials, inflatable forms can be manufactured at a lower cost, making them an attractive option for designers and manufacturers looking to reduce production expenses.

Applications of Inflatable 3dfx Forms

Inflatable 3dfx forms have a wide range of applications across various industries. Some of the most notable applications include:

- Product Design: Inflatable forms can be used to create complex shapes and designs for products, such as furniture, lighting fixtures, and even medical devices.

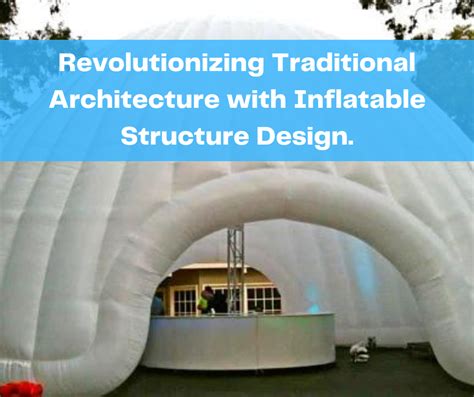

- Architecture: Inflatable forms can be used to create unique and innovative architectural designs, such as inflatable buildings, bridges, and even entire cities.

- Aerospace Engineering: Inflatable forms can be used to create lightweight and durable structures for aerospace applications, such as inflatable space habitats and spacecraft components.

Designing Inflatable 3dfx Forms

Designing inflatable 3dfx forms requires a deep understanding of materials science, physics, and mathematics. Designers must consider factors such as material properties, inflation pressure, and structural integrity to create complex shapes and forms.

To design inflatable 3dfx forms, designers can use a range of software tools, including computer-aided design (CAD) software and finite element analysis (FEA) software. These tools allow designers to simulate the behavior of inflatable forms under various conditions, including inflation pressure, temperature, and loading.

Manufacturing Inflatable 3dfx Forms

Manufacturing inflatable 3dfx forms requires specialized equipment and techniques. The most common manufacturing method for inflatable forms is injection molding, which involves injecting molten material into a mold to create the desired shape.

Other manufacturing methods for inflatable forms include casting, extrusion, and 3D printing. Each method has its advantages and disadvantages, and the choice of manufacturing method depends on the specific application and design requirements.

Challenges and Limitations

While inflatable 3dfx forms offer many benefits, there are also challenges and limitations to consider. One of the primary challenges is ensuring the structural integrity of inflatable forms, particularly under loading and pressure.

Another limitation of inflatable forms is their susceptibility to damage from punctures and abrasion. To overcome these challenges, designers and manufacturers must carefully select materials and design inflatable forms with safety and durability in mind.

Future of Inflatable 3dfx Forms

The future of inflatable 3dfx forms is exciting and promising. As technology continues to advance, we can expect to see even more innovative applications of inflatable forms across various industries.

One area of research that holds particular promise is the development of self-healing materials for inflatable forms. These materials can automatically repair punctures and damage, making inflatable forms even more durable and reliable.

In conclusion, inflatable 3dfx forms are revolutionizing the field of 3D form design, offering a unique combination of flexibility, durability, and cost-effectiveness. As technology continues to advance, we can expect to see even more innovative applications of inflatable forms across various industries.

We invite you to share your thoughts and experiences with inflatable 3dfx forms in the comments section below. Have you worked with inflatable forms before? What challenges and opportunities have you encountered? Share your insights and let's continue the conversation!

What are the primary benefits of inflatable 3dfx forms?

+The primary benefits of inflatable 3dfx forms include their flexibility, durability, and cost-effectiveness. Inflatable forms can be easily deflated and stored, making them ideal for applications where space is limited. Additionally, inflatable forms can be designed to be highly durable and resistant to damage, making them suitable for use in harsh environments.

What are the most common applications of inflatable 3dfx forms?

+Inflatable 3dfx forms have a wide range of applications across various industries, including product design, architecture, and aerospace engineering. Some of the most notable applications include creating complex shapes and designs for products, unique and innovative architectural designs, and lightweight and durable structures for aerospace applications.

What are the challenges and limitations of inflatable 3dfx forms?

+While inflatable 3dfx forms offer many benefits, there are also challenges and limitations to consider. One of the primary challenges is ensuring the structural integrity of inflatable forms, particularly under loading and pressure. Another limitation of inflatable forms is their susceptibility to damage from punctures and abrasion.