Hydrogen and nitrogen are two of the most abundant elements in the universe, and when combined, they form a vital compound called ammonia (NH3). The reaction between hydrogen and nitrogen to form ammonia is a complex process that has significant industrial and environmental implications. In this article, we will delve into the details of this reaction, its importance, and its various applications.

The Haber-Bosch Process

The reaction between hydrogen and nitrogen to form ammonia is known as the Haber-Bosch process, named after the German chemist Fritz Haber and the engineer Carl Bosch. This process involves the reaction of hydrogen gas (H2) with nitrogen gas (N2) to produce ammonia gas (NH3). The reaction occurs at high temperatures and pressures, typically between 400°C to 500°C and 200 to 300 atmospheres, respectively.

Chemical Equation and Reaction Mechanism

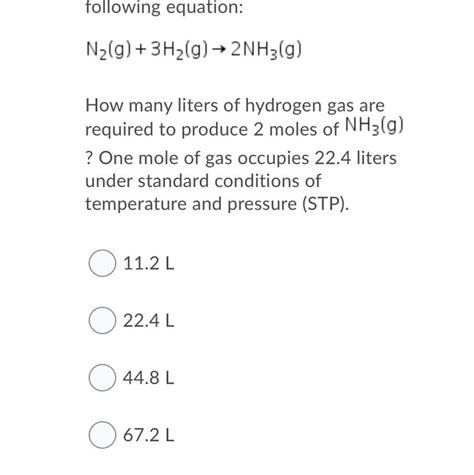

The chemical equation for the Haber-Bosch process is as follows:

N2 + 3H2 → 2NH3 + 92 kJ/mol

The reaction mechanism involves several steps, including the adsorption of nitrogen and hydrogen molecules onto the surface of a catalyst, such as iron or ruthenium. The nitrogen molecule is then broken down into nitrogen atoms, which react with hydrogen atoms to form ammonia.

Importance of Ammonia

Ammonia is a vital compound with numerous industrial, agricultural, and environmental applications. Some of the most significant uses of ammonia include:

- Fertilizer production: Ammonia is a key ingredient in the production of fertilizers, such as ammonium nitrate and urea. These fertilizers are essential for crop growth and food production.

- Refrigeration: Ammonia is used as a refrigerant in industrial refrigeration systems, due to its high latent heat of vaporization and low environmental impact.

- Cleaning products: Ammonia is a common ingredient in cleaning products, such as glass cleaners and disinfectants.

- Pharmaceuticals: Ammonia is used in the production of certain pharmaceuticals, such as antibiotics and vaccines.

Environmental Impact**

The production of ammonia through the Haber-Bosch process has significant environmental implications. Some of the concerns include:

- Energy consumption: The Haber-Bosch process requires large amounts of energy, typically in the form of natural gas or coal. This energy consumption contributes to greenhouse gas emissions and climate change.

- Nitrogen oxide emissions: The production of ammonia can result in the emission of nitrogen oxides, which are potent greenhouse gases and air pollutants.

- Water pollution: The production of ammonia can also result in water pollution, particularly if the process involves the use of wastewater or contaminated water sources.

Sustainable Alternatives

In recent years, researchers have been exploring sustainable alternatives to the Haber-Bosch process. Some of these alternatives include:

- Electrochemical synthesis: This process involves the use of electricity to synthesize ammonia from nitrogen and hydrogen. This method has the potential to be more energy-efficient and environmentally friendly.

- Biological synthesis: This process involves the use of microorganisms, such as bacteria or yeast, to synthesize ammonia from nitrogen and hydrogen. This method has the potential to be more energy-efficient and environmentally friendly.

- Solar-powered synthesis: This process involves the use of solar energy to synthesize ammonia from nitrogen and hydrogen. This method has the potential to be more energy-efficient and environmentally friendly.

Benefits of Sustainable Alternatives

The benefits of sustainable alternatives to the Haber-Bosch process include:

- Reduced energy consumption: Sustainable alternatives have the potential to reduce energy consumption and greenhouse gas emissions.

- Improved environmental sustainability: Sustainable alternatives have the potential to reduce environmental impacts, such as nitrogen oxide emissions and water pollution.

- Increased energy security: Sustainable alternatives have the potential to increase energy security by reducing dependence on fossil fuels.

Conclusion

In conclusion, the reaction between hydrogen and nitrogen to form ammonia gas is a complex process with significant industrial and environmental implications. While the Haber-Bosch process has been the dominant method of ammonia production for decades, sustainable alternatives are emerging as more energy-efficient and environmentally friendly options. As the world continues to grapple with the challenges of climate change and environmental sustainability, it is essential to explore and develop sustainable alternatives to traditional industrial processes.

We invite you to share your thoughts and comments on this article. How do you think sustainable alternatives to the Haber-Bosch process can make a difference in reducing environmental impacts? What other sustainable alternatives do you think have the potential to transform industrial processes?

What is the Haber-Bosch process?

+The Haber-Bosch process is a chemical reaction that combines hydrogen gas (H2) with nitrogen gas (N2) to produce ammonia gas (NH3). The reaction occurs at high temperatures and pressures, typically between 400°C to 500°C and 200 to 300 atmospheres, respectively.

What are the importance of ammonia?

+Ammonia is a vital compound with numerous industrial, agricultural, and environmental applications. Some of the most significant uses of ammonia include fertilizer production, refrigeration, cleaning products, and pharmaceuticals.

What are the environmental impacts of ammonia production?

+The production of ammonia through the Haber-Bosch process has significant environmental implications, including energy consumption, nitrogen oxide emissions, and water pollution.