Maintaining a safe and healthy work environment is crucial for industries that involve hazardous materials or chemicals. One of the most critical safety measures is the installation of eyewash stations. These stations provide immediate relief in case of chemical splashes or other eye injuries. However, simply installing an eyewash station is not enough; regular inspections are necessary to ensure that the equipment is functioning correctly and providing the necessary protection. In this article, we will discuss the 7 essential checks for eyewash station inspection.

Importance of Regular Eyewash Station Inspection

Regular inspections of eyewash stations are vital to ensure that they are functioning correctly and providing the necessary protection in case of an emergency. A faulty or malfunctioning eyewash station can lead to severe eye injuries, which can have long-term consequences for the victim. In addition, regular inspections can help identify potential issues before they become major problems, reducing downtime and maintenance costs.

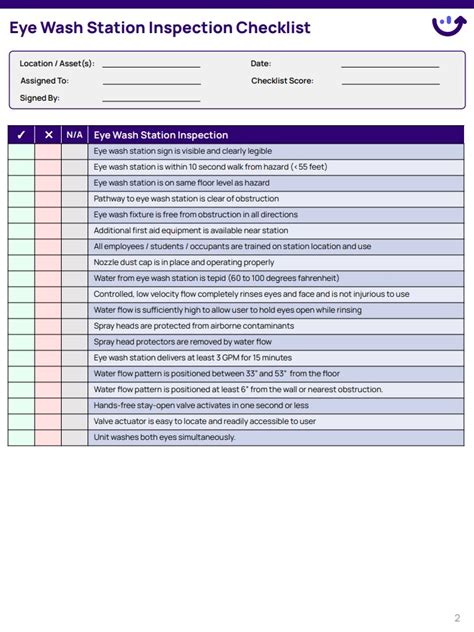

Essential Checks for Eyewash Station Inspection

Here are the 7 essential checks that you should perform during an eyewash station inspection:

1. Location and Accessibility

The first check is to ensure that the eyewash station is located in an area that is easily accessible in case of an emergency. The station should be installed in a well-lit area, and the path to the station should be clear of any obstacles. The station should also be located close to the area where hazardous materials are being handled.

2. Water Temperature and Pressure

The second check is to ensure that the water temperature and pressure are within the recommended range. The water temperature should be between 60°F and 100°F (15°C and 38°C), and the water pressure should be between 30 and 90 psi (2 and 6 bar). If the water temperature or pressure is outside this range, it can cause discomfort or injury to the user.

3. Water Flow Rate

The third check is to ensure that the water flow rate is within the recommended range. The water flow rate should be at least 20 gallons per minute (GPM) for a minimum of 15 minutes. If the water flow rate is too low, it may not provide sufficient flushing to remove contaminants from the eyes.

4. Nozzle and Spray Pattern

The fourth check is to ensure that the nozzle and spray pattern are functioning correctly. The nozzle should be designed to provide a wide spray pattern to cover the entire eye area. The spray pattern should also be gentle enough not to cause discomfort or injury to the user.

5. Valve and Handle

The fifth check is to ensure that the valve and handle are functioning correctly. The valve should be easy to operate, and the handle should be designed to stay open without any assistance. The valve and handle should also be designed to prevent accidental closure.

6. Drain and Waste

The sixth check is to ensure that the drain and waste system are functioning correctly. The drain should be designed to prevent any chemicals or contaminants from entering the drainage system. The waste system should also be designed to prevent any chemicals or contaminants from being released into the environment.

7. Inspection and Maintenance Records

The seventh and final check is to ensure that inspection and maintenance records are up to date. The records should include the date and time of the inspection, the results of the inspection, and any maintenance or repairs that were performed.

Conclusion

Regular inspections of eyewash stations are crucial to ensure that they are functioning correctly and providing the necessary protection in case of an emergency. By performing the 7 essential checks outlined in this article, you can help ensure that your eyewash stations are functioning correctly and providing the necessary protection for your employees.

How often should I inspect my eyewash station?

+It is recommended to inspect your eyewash station at least once a week, or more often if the station is used frequently.

What should I do if I find any issues during the inspection?

+If you find any issues during the inspection, you should report them to your supervisor or maintenance personnel immediately. They should be repaired or replaced as soon as possible.

Can I perform the inspection myself?

+While it is possible to perform the inspection yourself, it is recommended to have a trained professional perform the inspection to ensure that it is done correctly and thoroughly.