Concrete form tubes, also known as Sonotubes or cardboard tubes, have become a popular choice for fence post installation. These innovative tubes provide a quick, easy, and cost-effective solution for setting fence posts, and they have numerous benefits over traditional installation methods. In this article, we will explore the advantages of using concrete form tubes for fence posts, discuss the installation process, and provide tips for a successful project.

Benefits of Concrete Form Tubes for Fence Posts

Concrete form tubes offer several benefits that make them an attractive option for fence post installation. Here are some of the most significant advantages:

- Easy to install: Concrete form tubes are lightweight and easy to handle, making them perfect for DIY projects or for contractors who need to work efficiently.

- Cost-effective: Compared to traditional installation methods, concrete form tubes are relatively inexpensive, which can help reduce the overall cost of your fence installation project.

- Flexible: Concrete form tubes can be used for various types of fences, including wood, metal, and vinyl, and they can accommodate different post sizes and shapes.

- Durability: Concrete form tubes are designed to withstand harsh weather conditions and can last for many years without deteriorating.

How to Install Concrete Form Tubes for Fence Posts

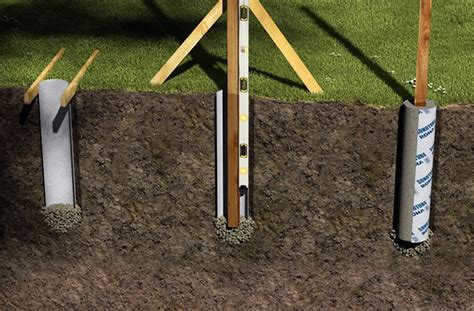

Installing concrete form tubes for fence posts is a relatively straightforward process that requires some basic tools and materials. Here's a step-by-step guide to help you get started:

- Prepare the site: Before you begin, make sure the area is clear of debris and obstructions. Mark the location of the fence posts with stakes and twine.

- Dig the holes: Use a post hole digger or a power auger to dig holes for the fence posts. The holes should be about 12 inches deep and slightly wider than the post.

- Cut the tubes: Cut the concrete form tubes to the desired length using a utility knife or a saw.

- Place the tubes: Insert the tubes into the holes, making sure they are level and plumb.

- Fill with concrete: Fill the tubes with concrete, making sure to fill them to the top.

- Set the post: Insert the fence post into the tube, making sure it is level and secure.

- Finish the installation: Fill the gap between the post and the tube with concrete, and finish the installation by adding any necessary trim or caps.

Tips for a Successful Installation

To ensure a successful installation, follow these tips:

- Use the right size tube: Make sure the tube is the right size for the post and the hole.

- Use a level: Ensure the tube is level and plumb to prevent the post from leaning.

- Use enough concrete: Fill the tube with enough concrete to secure the post.

- Finish the installation: Complete the installation by adding any necessary trim or caps.

Common Mistakes to Avoid

Here are some common mistakes to avoid when installing fence posts with concrete form tubes:

- Not using a level: Failing to ensure the tube is level and plumb can result in a leaning post.

- Not using enough concrete: Insufficient concrete can compromise the stability of the post.

- Not finishing the installation: Failing to complete the installation can leave the post vulnerable to damage.

Conclusion

Concrete form tubes are a game-changer for fence post installation. They offer a quick, easy, and cost-effective solution that can save you time and money. By following the installation process and tips outlined in this article, you can ensure a successful project that will provide years of durability and stability. So, next time you're planning a fence installation project, consider using concrete form tubes – your wallet and your back will thank you!What is the recommended depth for fence post holes?

+The recommended depth for fence post holes is about 12 inches deep and slightly wider than the post.

Can I use concrete form tubes for metal fence posts?

+Yes, concrete form tubes can be used for metal fence posts. However, you may need to use a specialized tube designed for metal posts.

How long do concrete form tubes last?

+Concrete form tubes are designed to last for many years, but their lifespan depends on various factors, including weather conditions and soil quality.