Rutting is a critical process in road construction and maintenance, and understanding the Rut 7 form is essential for ensuring that roads are built and maintained to last. In this article, we will delve into the world of rutting, exploring what it is, how it affects roads, and what the Rut 7 form is all about.

Rutting is a complex phenomenon that involves the deformation of asphalt pavements under traffic loading. It is a common issue in many parts of the world, particularly in regions with high temperatures and heavy traffic volumes. Rutting can lead to a range of problems, including reduced road safety, increased maintenance costs, and decreased road user satisfaction.

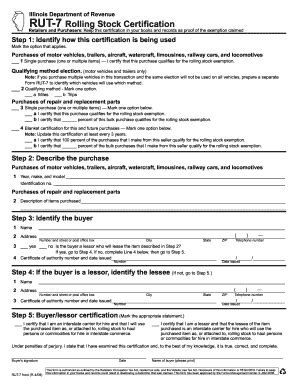

So, what is the Rut 7 form? Simply put, the Rut 7 form is a standardized method for measuring and reporting rut depths in asphalt pavements. It is a widely used tool in the road construction and maintenance industry, and is recognized by many transportation agencies around the world.

Understanding Rutting

Before we dive into the details of the Rut 7 form, it's essential to understand the concept of rutting. Rutting is a type of distress that occurs in asphalt pavements, characterized by the formation of longitudinal depressions or grooves in the surface of the road. These depressions can be caused by a range of factors, including traffic loading, temperature fluctuations, and inadequate pavement design or construction.

Rutting can have serious consequences for road safety and maintenance. For example, deep ruts can reduce the skid resistance of the road surface, increasing the risk of accidents. Additionally, rutting can lead to increased maintenance costs, as roads may need to be resurfaced or reconstructed more frequently.

Causes of Rutting

So, what causes rutting? There are several factors that can contribute to the formation of ruts in asphalt pavements. Some of the most common causes include:

- Traffic loading: Heavy traffic volumes and loads can cause the asphalt surface to deform and form ruts.

- Temperature fluctuations: Extreme temperature fluctuations can cause the asphalt to expand and contract, leading to the formation of ruts.

- Inadequate pavement design or construction: Poorly designed or constructed pavements can be more prone to rutting.

- Material deficiencies: Using low-quality materials or inadequate material thickness can increase the risk of rutting.

The Rut 7 Form

Now that we've covered the basics of rutting, let's take a closer look at the Rut 7 form. The Rut 7 form is a standardized method for measuring and reporting rut depths in asphalt pavements. It is widely used in the road construction and maintenance industry, and is recognized by many transportation agencies around the world.

The Rut 7 form provides a simple and effective way to measure and report rut depths, allowing road maintenance teams to quickly identify and address rutting issues. The form includes a range of fields for recording information, including:

- Location: The location of the rut, including the road name and distance from a reference point.

- Rut depth: The depth of the rut, measured in millimeters or inches.

- Rut width: The width of the rut, measured in millimeters or inches.

- Pavement type: The type of pavement, including the asphalt mix design and layer thickness.

Benefits of the Rut 7 Form

So, what are the benefits of using the Rut 7 form? Some of the key advantages include:

- Improved accuracy: The Rut 7 form provides a standardized method for measuring and reporting rut depths, reducing the risk of errors or inconsistencies.

- Increased efficiency: The form allows road maintenance teams to quickly identify and address rutting issues, reducing the time and resources required for maintenance.

- Enhanced safety: By identifying and addressing rutting issues, road maintenance teams can improve road safety and reduce the risk of accidents.

Best Practices for Measuring Rut Depths

Measuring rut depths accurately is critical for ensuring that roads are built and maintained to last. Here are some best practices for measuring rut depths using the Rut 7 form:

- Use a calibrated measuring device: Ensure that your measuring device is calibrated and accurate, to avoid errors or inconsistencies.

- Measure at regular intervals: Measure rut depths at regular intervals, such as every 10 meters or 30 feet.

- Record all data: Record all data, including the location, rut depth, rut width, and pavement type.

Common Mistakes to Avoid

When measuring rut depths, there are several common mistakes to avoid. Some of the most common errors include:

- Inaccurate measurements: Ensure that your measuring device is calibrated and accurate, to avoid errors or inconsistencies.

- Incomplete data: Record all data, including the location, rut depth, rut width, and pavement type.

- Failure to follow procedures: Follow established procedures for measuring and reporting rut depths, to ensure consistency and accuracy.

Conclusion

In conclusion, the Rut 7 form is a powerful tool for measuring and reporting rut depths in asphalt pavements. By understanding the causes of rutting and using the Rut 7 form, road maintenance teams can quickly identify and address rutting issues, improving road safety and reducing maintenance costs. Remember to follow best practices for measuring rut depths, and avoid common mistakes to ensure accurate and consistent results.

We hope this article has provided valuable insights into the world of rutting and the Rut 7 form. If you have any questions or comments, please don't hesitate to share them with us.

What is rutting?

+Rutting is a type of distress that occurs in asphalt pavements, characterized by the formation of longitudinal depressions or grooves in the surface of the road.

What is the Rut 7 form?

+The Rut 7 form is a standardized method for measuring and reporting rut depths in asphalt pavements.

What are the benefits of using the Rut 7 form?

+The benefits of using the Rut 7 form include improved accuracy, increased efficiency, and enhanced safety.