Equipment inspection is a crucial aspect of maintaining workplace safety and preventing accidents. Regular inspections help identify potential hazards and ensure that equipment is in good working condition. In this article, we will discuss the importance of JLG equipment inspection and provide a comprehensive guide on how to conduct a thorough inspection.

Why is JLG Equipment Inspection Important?

JLG equipment, such as aerial lifts and boom lifts, are commonly used in construction, maintenance, and other industries. These machines can pose significant risks if not properly maintained. Regular inspections help identify potential hazards, such as worn-out parts, malfunctioning systems, and other safety issues. By conducting regular inspections, you can ensure that your JLG equipment is in good working condition, reducing the risk of accidents and injuries.

Benefits of Regular Equipment Inspections

Regular equipment inspections offer numerous benefits, including:

- Improved workplace safety: By identifying potential hazards, you can take corrective action to prevent accidents and injuries.

- Reduced equipment downtime: Regular inspections help identify maintenance needs, reducing the likelihood of unexpected breakdowns.

- Extended equipment lifespan: Regular maintenance can help extend the lifespan of your JLG equipment, reducing the need for costly repairs or replacements.

- Compliance with regulations: Regular inspections help ensure compliance with industry regulations and standards.

Pre-Inspection Checklist

Before conducting a JLG equipment inspection, it's essential to gather the necessary information and tools. Here's a pre-inspection checklist to help you prepare:

- Review the equipment's manual and maintenance records

- Gather the necessary tools and equipment, such as a ladder, wrench, and inspection forms

- Identify the inspection scope and objectives

- Ensure that the equipment is in a safe condition for inspection

Conducting a JLG Equipment Inspection

A comprehensive JLG equipment inspection should include the following steps:

h3>Visual Inspection

- Inspect the equipment's exterior and interior for signs of damage or wear

- Check for loose or missing parts, such as bolts, nuts, or wires

- Look for signs of corrosion or rust

- Check the equipment's hydraulic and electrical systems for leaks or damage

Functional Inspection

- Test the equipment's controls and functions, such as the boom's extension and retraction

- Check the equipment's stability and balance

- Test the equipment's safety features, such as the alarm system and emergency shutdown

Mechanical Inspection

- Inspect the equipment's mechanical components, such as the engine, transmission, and brakes

- Check the equipment's tire condition and pressure

- Inspect the equipment's hydraulic system, including the hoses, pumps, and valves

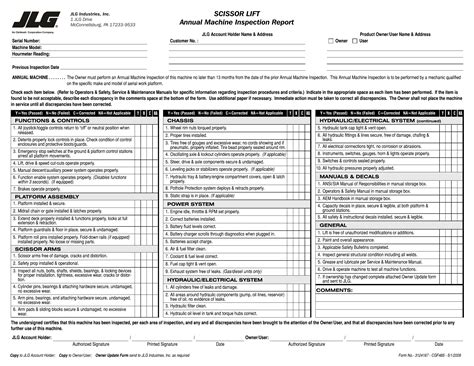

JLG Equipment Inspection Form

A JLG equipment inspection form is a crucial tool for conducting a thorough inspection. The form should include the following sections:

- Equipment information: Make, model, serial number, and location

- Inspection scope and objectives

- Visual inspection checklist

- Functional inspection checklist

- Mechanical inspection checklist

- Findings and recommendations

- Signature and date

Best Practices for JLG Equipment Inspection

To ensure a thorough and effective inspection, follow these best practices:

- Use a standardized inspection form and procedure

- Conduct regular inspections, ideally on a daily or weekly basis

- Involve multiple personnel in the inspection process

- Document all findings and recommendations

- Address any safety concerns or issues immediately

Common Hazards and Safety Concerns

JLG equipment can pose several hazards and safety concerns, including:

- Falls from heights

- Crushing or pinning

- Electrical shock

- Hydraulic fluid leaks

- Fire hazards

Safety Precautions and Personal Protective Equipment

To ensure a safe inspection process, follow these safety precautions and wear the necessary personal protective equipment (PPE):

- Hard hat and safety glasses

- Steel-toed boots and gloves

- Fall protection equipment, such as a harness and lanyard

- Electrical insulation gloves and sleeves

Conclusion: Stay Safe with Regular JLG Equipment Inspections

Regular JLG equipment inspections are crucial for maintaining workplace safety and preventing accidents. By following this comprehensive guide, you can ensure that your equipment is in good working condition and identify potential hazards before they become major issues. Remember to always prioritize safety and take corrective action to address any safety concerns or issues.

What is the recommended frequency for JLG equipment inspections?

+The recommended frequency for JLG equipment inspections varies depending on the equipment's usage and environment. However, daily or weekly inspections are recommended to ensure optimal performance and safety.

What are the most common hazards associated with JLG equipment?

+The most common hazards associated with JLG equipment include falls from heights, crushing or pinning, electrical shock, hydraulic fluid leaks, and fire hazards.

What personal protective equipment (PPE) is recommended for JLG equipment inspections?

+The recommended PPE for JLG equipment inspections includes hard hats, safety glasses, steel-toed boots, gloves, fall protection equipment, and electrical insulation gloves and sleeves.