The Formlabs Form Wash is a crucial tool for post-processing 3D prints, especially for those who work with resin-based materials. Its ability to efficiently clean and remove support material makes it an indispensable part of many 3D printing workflows. However, like any machine, it can be optimized for better performance and longevity. In this article, we'll explore five ways to optimize your Formlabs Form Wash.

Understanding the Formlabs Form Wash

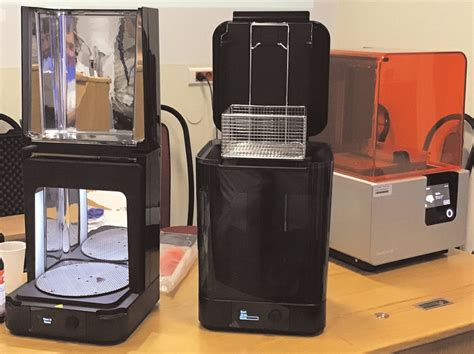

Before we dive into optimization techniques, it's essential to understand how the Formlabs Form Wash works. The device uses a combination of mechanical agitation and solvent to remove support material and residue from 3D prints. The wash process involves submerging the print in a solvent bath, which is agitated by a mechanical system to dislodge and remove support material. Once the wash cycle is complete, the print is removed, and the solvent is filtered and reused.

1. Regular Maintenance and Cleaning

Regular maintenance and cleaning are crucial to ensuring the Formlabs Form Wash operates efficiently and effectively. Here are some tips to help you keep your device in top condition:

- Filter the solvent regularly: The solvent filter should be cleaned or replaced regularly to prevent clogging and maintain the quality of the solvent.

- Clean the tank and mechanical components: Regularly clean the tank, mechanical components, and other parts of the device to prevent residue buildup.

- Check and replace worn-out parts: Inspect the device regularly and replace worn-out parts, such as seals and gaskets, to prevent leaks and maintain performance.

2. Optimizing Wash Cycles

Optimizing wash cycles can significantly improve the performance of your Formlabs Form Wash. Here are some tips to help you get the most out of your device:

- Adjust the wash time and intensity: Experiment with different wash times and intensities to find the optimal settings for your specific 3D printing materials and print geometries.

- Use the correct solvent temperature: Ensure the solvent is at the optimal temperature for the material you're working with. This can improve the effectiveness of the wash cycle and prevent damage to the print.

- Use a wash cycle for sensitive prints: If you're working with sensitive or delicate prints, consider using a gentle wash cycle to prevent damage.

3. Solvent Management

Effective solvent management is critical to maintaining the performance and longevity of your Formlabs Form Wash. Here are some tips to help you manage your solvent:

- Use the correct solvent: Ensure you're using the recommended solvent for your specific 3D printing material. Using the wrong solvent can reduce the effectiveness of the wash cycle and damage the print.

- Monitor solvent levels: Regularly check the solvent level and top it off as needed. This will prevent the device from running dry and reduce the risk of damage.

- Dispose of solvent responsibly: Dispose of used solvent responsibly and in accordance with local regulations.

4. Post-Wash Processing

Post-wash processing is an essential step in the 3D printing workflow. Here are some tips to help you get the most out of your Formlabs Form Wash:

- Use a drying station: Consider using a drying station to remove excess solvent and prevent water spots.

- Apply a post-wash treatment: Apply a post-wash treatment, such as a cleaning solution or sealant, to protect the print and enhance its appearance.

- Inspect and handle prints carefully: Inspect prints carefully after washing and handle them gently to prevent damage.

5. Upgrades and Accessories

Formlabs offers a range of upgrades and accessories for the Form Wash, including upgraded mechanical components and specialized wash baskets. Here are some tips to help you choose the right upgrades and accessories for your device:

- Upgrade to a high-performance wash basket: Consider upgrading to a high-performance wash basket, which can improve wash cycle efficiency and effectiveness.

- Add a solvent heater: A solvent heater can improve wash cycle effectiveness and reduce the risk of damage to sensitive prints.

- Use a wash basket liner: A wash basket liner can prevent residue buildup and make cleaning easier.

By following these five optimization techniques, you can improve the performance and longevity of your Formlabs Form Wash. Regular maintenance and cleaning, optimizing wash cycles, effective solvent management, post-wash processing, and upgrades and accessories can all contribute to a more efficient and effective 3D printing workflow.

We'd love to hear about your experiences with the Formlabs Form Wash! Share your tips and tricks for optimizing your device in the comments below.

What is the recommended solvent for the Formlabs Form Wash?

+The recommended solvent for the Formlabs Form Wash is Form Wash Solvent, which is specifically designed for use with Formlabs resin-based 3D printing materials.

How often should I clean and maintain my Formlabs Form Wash?

+Regular cleaning and maintenance is recommended to ensure optimal performance and longevity of the device. Clean the tank and mechanical components regularly, and check and replace worn-out parts as needed.

Can I use the Formlabs Form Wash with other 3D printing materials?

+The Formlabs Form Wash is specifically designed for use with Formlabs resin-based 3D printing materials. Using the device with other materials may not be effective and may damage the print or the device.