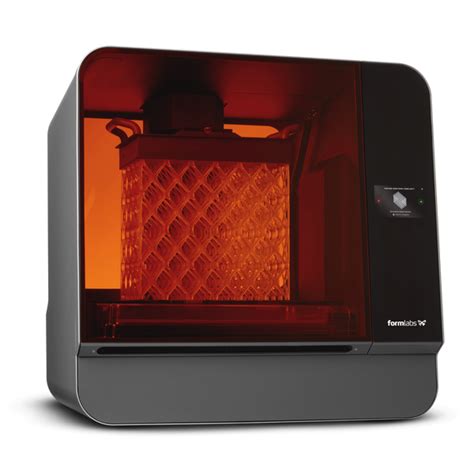

The Form 3L printer is a powerful tool for creating high-quality 3D prints, but it can be intimidating for those new to 3D printing or unfamiliar with the specifics of this machine. With its advanced features and capabilities, mastering the Form 3L printer requires a combination of technical knowledge, practical experience, and attention to detail. In this article, we'll explore five essential tips for getting the most out of your Form 3L printer and achieving professional-grade prints.

Tip 1: Understand the Basics of Resin Printing

Before diving into the specifics of the Form 3L printer, it's essential to understand the basics of resin printing. Unlike FDM (Fused Deposition Modeling) printing, which uses melted plastic to create prints, resin printing uses a liquid resin that's cured with light. This process produces highly detailed prints with smooth surfaces, but it also requires a deeper understanding of the printing process.

To get started, familiarize yourself with the different types of resin available, including standard resin, flexible resin, and dental resin. Each type has its unique properties and applications, so it's crucial to choose the right one for your specific project.

Additionally, understand the importance of post-curing, which involves exposing the printed part to UV light to fully cure the resin. This step is critical for achieving optimal mechanical properties and ensuring the print is safe to handle.

Key Takeaways:

- Resin printing uses liquid resin cured with light

- Different types of resin have unique properties and applications

- Post-curing is essential for optimal mechanical properties and safety

Tip 2: Optimize Your Print Settings

The Form 3L printer offers a wide range of print settings that can be adjusted to achieve optimal results. To get the most out of your printer, it's essential to understand how to optimize these settings for your specific project.

Start by adjusting the layer thickness, which controls the level of detail and the print time. Thicker layers result in faster print times but may compromise on detail, while thinner layers produce more detailed prints but take longer to complete.

Next, adjust the exposure time and intensity, which control the amount of light the resin receives. Increasing the exposure time or intensity can result in more accurate prints, but be careful not to over-expose, which can cause the resin to become brittle.

Finally, experiment with different support settings, which control the amount of support material generated during the print process. Adjusting the support settings can help reduce waste and improve print accuracy.

Key Takeaways:

- Adjust layer thickness to control detail and print time

- Adjust exposure time and intensity to control print accuracy

- Experiment with support settings to reduce waste and improve accuracy

Tip 3: Maintain Your Printer Regularly

Regular maintenance is essential for ensuring your Form 3L printer continues to produce high-quality prints. Start by cleaning the printer regularly, paying attention to the resin tank, build platform, and optical module.

Next, perform routine calibrations to ensure the printer is accurately aligned and functioning properly. This includes calibrating the build platform, optical module, and resin tank.

Finally, replace worn-out parts, such as the resin tank and build platform, to maintain optimal print quality.

Key Takeaways:

- Clean the printer regularly to prevent resin buildup

- Perform routine calibrations to ensure accurate alignment and function

- Replace worn-out parts to maintain optimal print quality

Tip 4: Troubleshoot Common Issues

Despite regular maintenance, issues can still arise during the print process. To minimize downtime and ensure optimal print quality, it's essential to troubleshoot common issues effectively.

Start by identifying the source of the problem, whether it's a hardware issue, software glitch, or print setting error. Next, consult the user manual or online resources for troubleshooting guides specific to your issue.

Common issues to watch out for include:

- Resin not curing properly

- Prints not adhering to the build platform

- Optical module malfunctioning

Key Takeaways:

- Identify the source of the problem to troubleshoot effectively

- Consult user manuals or online resources for troubleshooting guides

- Common issues include resin curing, print adhesion, and optical module malfunction

Tip 5: Experiment and Push Boundaries

Finally, don't be afraid to experiment and push the boundaries of what's possible with your Form 3L printer. Try new print settings, experiment with different resins, and explore novel applications for your prints.

By pushing the limits of your printer, you can achieve unique and innovative results that showcase the full potential of the Form 3L. Whether you're a professional engineer, hobbyist, or artist, the Form 3L offers endless possibilities for creative expression and problem-solving.

Key Takeaways:

- Experiment with new print settings and resins to achieve unique results

- Explore novel applications for your prints to showcase the Form 3L's potential

- Don't be afraid to push boundaries and try new things

By following these five tips, you'll be well on your way to mastering the Form 3L printer and achieving professional-grade prints. Remember to always keep learning, experimenting, and pushing the boundaries of what's possible with this powerful tool.

Now it's your turn! Share your experiences, tips, and tricks for mastering the Form 3L printer in the comments below. What's your favorite thing to print with the Form 3L? Do you have any questions or need help troubleshooting an issue? Let's get the conversation started!

What is the best way to clean the Form 3L printer?

+The best way to clean the Form 3L printer is to use a soft cloth and a mild detergent. Avoid using harsh chemicals or abrasive materials that can damage the printer's components.

How do I troubleshoot common issues with the Form 3L printer?

+Consult the user manual or online resources for troubleshooting guides specific to your issue. Identify the source of the problem and take corrective action to resolve the issue.

What is the best way to optimize print settings for the Form 3L printer?

+Adjust the layer thickness, exposure time, and intensity to achieve optimal results. Experiment with different support settings to reduce waste and improve accuracy.