The world of programmable logic controllers (PLCs) can seem intimidating, especially when it comes to understanding counter instructions. However, with a clear explanation, you'll be able to grasp the concept and apply it to your PLC programming needs.

A counter instruction is a fundamental element in PLC programming that allows you to count events, such as the number of products on a conveyor belt or the number of times a machine has cycled. In this article, we'll break down the basics of PLC counter instructions, their types, and how to use them effectively.

What is a PLC Counter Instruction?

A PLC counter instruction is a programming element that increments or decrements a value based on a specific condition or event. It's essentially a digital counter that can be used to keep track of various events, such as the number of parts produced, the number of times a door opens, or the number of errors that occur.

Types of PLC Counter Instructions

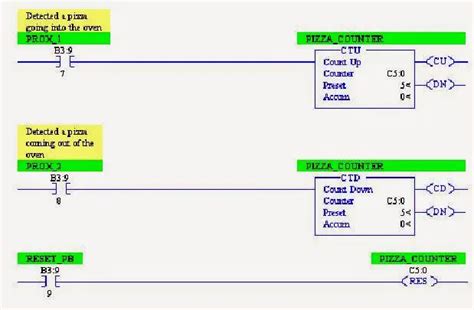

There are two primary types of PLC counter instructions: up counters and down counters.

- Up Counter: An up counter increments a value when a specific condition is met. For example, if you're counting the number of products on a conveyor belt, an up counter would increment the count each time a product passes a sensor.

- Down Counter: A down counter decrements a value when a specific condition is met. For example, if you're counting the number of remaining products in a batch, a down counter would decrement the count each time a product is removed.

Additional Counter Instructions

In addition to up and down counters, there are other types of counter instructions, including:

- Reset Counter: A reset counter resets the count to zero when a specific condition is met.

- Load Counter: A load counter loads a predefined value into the counter.

- Compare Counter: A compare counter compares the current count to a predefined value.

How to Use PLC Counter Instructions

To use PLC counter instructions effectively, follow these steps:

- Define the Counter: Define the counter instruction in your PLC program, specifying the type of counter and the conditions under which it should increment or decrement.

- Assign the Counter: Assign the counter to a specific memory location or variable.

- Configure the Conditions: Configure the conditions under which the counter should increment or decrement, such as a sensor input or a timer event.

- Monitor the Counter: Monitor the counter value to ensure it's accurate and functioning as expected.

Best Practices for Using PLC Counter Instructions

To get the most out of PLC counter instructions, follow these best practices:

- Use Clear and Concise Programming: Use clear and concise programming to define the counter instruction and its conditions.

- Test the Counter: Test the counter thoroughly to ensure it's functioning as expected.

- Document the Counter: Document the counter instruction and its usage to ensure easy troubleshooting and maintenance.

Common Applications of PLC Counter Instructions

PLC counter instructions have a wide range of applications, including:

- Manufacturing: Counting the number of products produced, monitoring production rates, and tracking inventory levels.

- Quality Control: Monitoring the number of defects or errors in a production process.

- Machine Automation: Counting the number of cycles or operations performed by a machine.

Real-World Examples of PLC Counter Instructions

Here are some real-world examples of PLC counter instructions:

- Conveyor Belt Counter: A conveyor belt counter increments the count each time a product passes a sensor, allowing the system to track the number of products produced.

- Door Open/Close Counter: A door open/close counter increments the count each time a door opens or closes, allowing the system to track the number of times the door has been accessed.

Conclusion

In conclusion, PLC counter instructions are a powerful tool for tracking events and monitoring processes in industrial automation. By understanding the different types of counter instructions and how to use them effectively, you can improve the efficiency and accuracy of your PLC programs.

Whether you're a seasoned PLC programmer or just starting out, we hope this article has provided valuable insights into the world of PLC counter instructions. If you have any questions or comments, please don't hesitate to reach out.

Take the next step and start exploring the world of PLC programming. Share your thoughts and experiences in the comments below!

What is the main function of a PLC counter instruction?

+The main function of a PLC counter instruction is to increment or decrement a value based on a specific condition or event.

What are the two primary types of PLC counter instructions?

+The two primary types of PLC counter instructions are up counters and down counters.

What is the purpose of a reset counter instruction?

+The purpose of a reset counter instruction is to reset the count to zero when a specific condition is met.