Choppers and big form cutting tools have revolutionized the way we approach metal fabrication, woodworking, and other industries that require precise cutting. These powerful tools have enabled professionals and hobbyists alike to tackle complex projects with ease, accuracy, and speed. In this comprehensive guide, we will delve into the world of high-power cutting, exploring the benefits, types, and applications of choppers and big form cutting tools.

The Importance of High-Power Cutting

High-power cutting tools have become an essential part of various industries, including metal fabrication, woodworking, and construction. These tools enable users to cut through tough materials quickly and efficiently, reducing labor time and increasing productivity. Moreover, high-power cutting tools provide a high level of accuracy, allowing for precise cuts and minimizing waste.

Types of High-Power Cutting Tools

There are several types of high-power cutting tools available, each designed for specific applications and industries. Some of the most common types include:

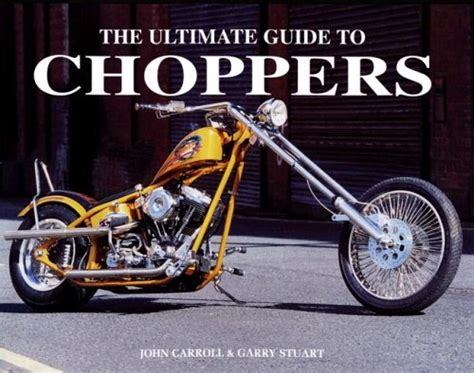

- Choppers: Choppers are heavy-duty cutting tools designed for cutting through thick metal pipes, bars, and plates. They are commonly used in metal fabrication, construction, and demolition industries.

- Band Saws: Band saws are versatile cutting tools that use a continuous loop of metal with teeth on one edge to cut through various materials. They are widely used in woodworking, metalworking, and other industries.

- Circular Saws: Circular saws are powerful cutting tools that use a rotating circular blade to cut through materials. They are commonly used in woodworking, metalworking, and construction industries.

Applications of High-Power Cutting Tools

High-power cutting tools have a wide range of applications across various industries. Some of the most common applications include:

- Metal Fabrication: High-power cutting tools are essential in metal fabrication, where they are used to cut through thick metal pipes, bars, and plates.

- Woodworking: High-power cutting tools are widely used in woodworking, where they are used to cut through wood, plywood, and other wood products.

- Construction: High-power cutting tools are commonly used in construction, where they are used to cut through metal pipes, wooden beams, and other construction materials.

Benefits of High-Power Cutting Tools

High-power cutting tools offer several benefits, including:

- Increased Productivity: High-power cutting tools enable users to cut through materials quickly and efficiently, reducing labor time and increasing productivity.

- Improved Accuracy: High-power cutting tools provide a high level of accuracy, allowing for precise cuts and minimizing waste.

- Reduced Labor Costs: High-power cutting tools reduce labor costs by minimizing the need for manual cutting and reducing the risk of injury.

Choosing the Right High-Power Cutting Tool

Choosing the right high-power cutting tool can be a daunting task, especially for those new to the industry. Here are some factors to consider when choosing a high-power cutting tool:

- Application: Consider the specific application of the cutting tool. Different tools are designed for different materials and industries.

- Power Source: Consider the power source of the cutting tool. Some tools are electric, while others are pneumatic or hydraulic.

- Blade Type: Consider the type of blade required for the application. Different blades are designed for different materials and cutting styles.

Maintenance and Safety

Proper maintenance and safety precautions are essential when using high-power cutting tools. Here are some tips to keep in mind:

- Regular Maintenance: Regular maintenance is essential to ensure the longevity and performance of the cutting tool.

- Safety Precautions: Always wear safety gear, including gloves, safety glasses, and a dust mask, when operating a high-power cutting tool.

- Operator Training: Ensure that operators are properly trained to use the cutting tool safely and efficiently.

Best Practices for High-Power Cutting

Here are some best practices to keep in mind when using high-power cutting tools:

- Use the Right Blade: Always use the right blade for the application to ensure accurate cuts and minimize waste.

- Maintain Proper Alignment: Maintain proper alignment of the cutting tool to ensure accurate cuts and minimize waste.

- Monitor Tool Condition: Regularly monitor the condition of the cutting tool to ensure optimal performance and longevity.

Future of High-Power Cutting

The future of high-power cutting is exciting, with advancements in technology and design expected to improve performance, efficiency, and safety. Some of the trends to watch out for include:

- Automation: Automation is expected to play a bigger role in high-power cutting, with machines and robots taking over repetitive and complex tasks.

- Sustainability: Sustainability is becoming increasingly important in high-power cutting, with manufacturers focusing on developing eco-friendly and energy-efficient tools.

- Advanced Materials: Advanced materials, such as composites and nanomaterials, are expected to play a bigger role in high-power cutting, offering improved performance and durability.

In conclusion, high-power cutting tools have revolutionized the way we approach metal fabrication, woodworking, and other industries. By choosing the right tool, following best practices, and maintaining proper safety precautions, users can achieve accurate cuts, increase productivity, and reduce labor costs. As technology continues to advance, we can expect to see even more exciting developments in the world of high-power cutting.

What is the most common type of high-power cutting tool?

+Choppers are the most common type of high-power cutting tool, widely used in metal fabrication, construction, and demolition industries.

What is the benefit of using a high-power cutting tool?

+High-power cutting tools offer several benefits, including increased productivity, improved accuracy, and reduced labor costs.

What safety precautions should I take when using a high-power cutting tool?

+Always wear safety gear, including gloves, safety glasses, and a dust mask, when operating a high-power cutting tool. Ensure proper training and follow best practices for safe operation.