In the world of plumbing and engineering, taps are an essential component that allows for the controlled flow of liquids and gases. Among the various types of taps available, Balax form taps are particularly popular due to their versatility and precision. These taps are designed to create internal threads in materials such as metal, plastic, and wood, making them a crucial tool in various industries. In this article, we will explore five ways to use Balax form taps, highlighting their applications, benefits, and steps for effective use.

Understanding Balax Form Taps

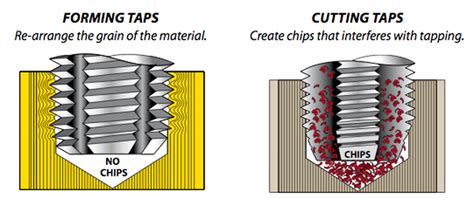

Before diving into the applications of Balax form taps, it is essential to understand their design and functionality. Unlike other types of taps, Balax form taps have a unique thread form that allows for precise control over the threading process. This feature makes them ideal for creating threads in materials with specific requirements, such as high-strength alloys or brittle plastics.

Key Features of Balax Form Taps

• Unique thread form for precise control over threading process • Designed for creating internal threads in various materials • High-quality construction for durability and longevity • Suitable for use in various industries, including aerospace, automotive, and manufacturing

Application 1: Aerospace Industry

The aerospace industry is one of the most demanding environments for engineering components, requiring precision, strength, and durability. Balax form taps are widely used in this industry to create threads in high-strength alloys, such as titanium and stainless steel. These taps are essential for creating precise threads in aircraft components, such as engine mounts, landing gear, and control surfaces.

Benefits of Using Balax Form Taps in Aerospace Industry

• Precise control over threading process ensures accurate thread dimensions • High-quality construction withstands extreme temperatures and stress • Suitable for use in high-strength alloys, reducing the risk of thread failure

Application 2: Automotive Industry

The automotive industry relies heavily on precision engineering to ensure the safety and performance of vehicles. Balax form taps are used in this industry to create threads in engine components, transmission parts, and suspension systems. These taps are essential for creating precise threads in materials such as aluminum, steel, and copper.

Benefits of Using Balax Form Taps in Automotive Industry

• Precise control over threading process ensures accurate thread dimensions • High-quality construction withstands extreme temperatures and stress • Suitable for use in various materials, reducing the risk of thread failure

Application 3: Manufacturing Industry

The manufacturing industry encompasses a wide range of applications, from production machinery to consumer goods. Balax form taps are used in this industry to create threads in various materials, including plastics, woods, and metals. These taps are essential for creating precise threads in components such as gears, pulleys, and bearings.

Benefits of Using Balax Form Taps in Manufacturing Industry

• Precise control over threading process ensures accurate thread dimensions • High-quality construction withstands extreme temperatures and stress • Suitable for use in various materials, reducing the risk of thread failure

Application 4: Woodworking Industry

The woodworking industry requires precision and accuracy to create high-quality furniture and wood products. Balax form taps are used in this industry to create threads in wood, allowing for the creation of precise joints and connections. These taps are essential for creating strong and durable wood products.

Benefits of Using Balax Form Taps in Woodworking Industry

• Precise control over threading process ensures accurate thread dimensions • High-quality construction withstands extreme stress and wear • Suitable for use in various types of wood, reducing the risk of thread failure

Application 5: DIY and Hobbyist Projects

Balax form taps are not limited to industrial applications; they are also useful for DIY and hobbyist projects. These taps can be used to create precise threads in materials such as metal, plastic, and wood, making them ideal for projects such as model making, robotics, and home repairs.

Benefits of Using Balax Form Taps in DIY and Hobbyist Projects

• Precise control over threading process ensures accurate thread dimensions • High-quality construction withstands extreme stress and wear • Suitable for use in various materials, reducing the risk of thread failure

In conclusion, Balax form taps are a versatile tool with a wide range of applications across various industries. Their unique thread form and high-quality construction make them an essential tool for creating precise threads in various materials. Whether you are a professional engineer or a DIY enthusiast, Balax form taps are an excellent choice for any project that requires precision and accuracy.

We encourage you to share your experiences with Balax form taps in the comments below. Have you used these taps in any of the applications mentioned above? What benefits or challenges have you encountered? Your input will help us create a more comprehensive resource for our readers.

What is the primary advantage of using Balax form taps?

+The primary advantage of using Balax form taps is their ability to create precise threads in various materials, ensuring accurate thread dimensions and reducing the risk of thread failure.

Can Balax form taps be used in high-temperature applications?

+Yes, Balax form taps are designed to withstand extreme temperatures and stress, making them suitable for use in high-temperature applications.

Are Balax form taps suitable for use in woodworking projects?

+Yes, Balax form taps are suitable for use in woodworking projects, allowing for the creation of precise threads in wood and reducing the risk of thread failure.