Free 90 Day Bit Inspection Form: A Comprehensive Guide

Are you tired of dealing with costly drilling equipment repairs and replacements? Do you want to ensure that your drilling operations run smoothly and efficiently? Look no further! A 90-day bit inspection form is a valuable tool that can help you monitor the condition of your drilling equipment and prevent unnecessary damage. In this article, we will delve into the importance of bit inspection, the benefits of using a 90-day bit inspection form, and provide a comprehensive guide on how to use it.

Why is Bit Inspection Important?

Bit inspection is a crucial aspect of drilling operations. Drilling equipment, particularly drill bits, are subject to wear and tear, which can lead to reduced efficiency, increased costs, and even safety hazards. Regular bit inspections can help identify potential issues before they become major problems, allowing you to take corrective action and prevent costly repairs.

Benefits of Regular Bit Inspection

- Reduced downtime and increased productivity

- Extended equipment lifespan

- Improved drilling efficiency and accuracy

- Enhanced safety

- Cost savings through reduced repair and replacement costs

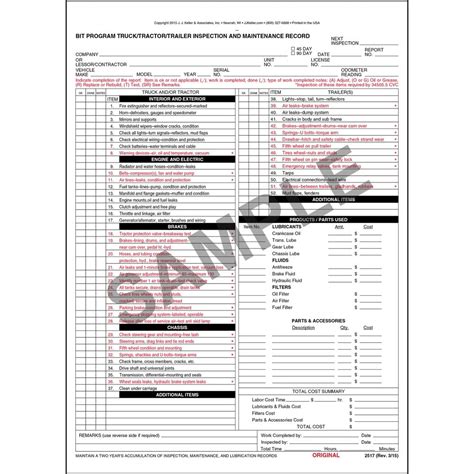

What is a 90-Day Bit Inspection Form?

A 90-day bit inspection form is a standardized document that helps drillers and drilling operators inspect and record the condition of their drilling equipment at regular intervals. The form typically includes a checklist of critical components, such as the drill bit, drill pipe, and drilling motor, and requires inspectors to rate their condition and note any defects or issues.

Benefits of Using a 90-Day Bit Inspection Form

- Ensures regular and consistent inspections

- Provides a standardized format for recording inspection data

- Helps identify trends and patterns in equipment wear and tear

- Facilitates communication between drillers, operators, and maintenance personnel

- Supports informed decision-making and maintenance planning

How to Use a 90-Day Bit Inspection Form

Using a 90-day bit inspection form is a straightforward process. Here's a step-by-step guide:

- Gather necessary information: Before starting the inspection, gather relevant information about the drilling equipment, including the make, model, and serial number.

- Conduct the inspection: Inspect the drilling equipment, paying attention to the critical components listed on the form.

- Record inspection data: Complete the inspection form, rating the condition of each component and noting any defects or issues.

- Review and analyze data: Review the inspection data to identify trends and patterns in equipment wear and tear.

- Take corrective action: Take corrective action to address any issues or defects identified during the inspection.

Download Your Free 90-Day Bit Inspection Form Now

Don't wait any longer to start improving your drilling operations. Download your free 90-day bit inspection form now and start monitoring the condition of your drilling equipment today.

Additional Tips for Effective Bit Inspection

- Use a standardized inspection form: Using a standardized inspection form ensures consistency and accuracy in your inspections.

- Train inspectors: Train inspectors on the proper use of the inspection form and the critical components to inspect.

- Schedule regular inspections: Schedule regular inspections to ensure that equipment is inspected at consistent intervals.

- Maintain accurate records: Maintain accurate records of inspection data to track trends and patterns in equipment wear and tear.

Conclusion

Regular bit inspection is crucial to ensuring the efficient and safe operation of drilling equipment. A 90-day bit inspection form is a valuable tool that can help drillers and drilling operators monitor the condition of their equipment and prevent unnecessary damage. By following the steps outlined in this article and downloading your free 90-day bit inspection form, you can take the first step towards improving your drilling operations.

What is the purpose of a 90-day bit inspection form?

+The purpose of a 90-day bit inspection form is to help drillers and drilling operators inspect and record the condition of their drilling equipment at regular intervals.

How often should I inspect my drilling equipment?

+Drilling equipment should be inspected at regular intervals, typically every 90 days.

What are the benefits of using a 90-day bit inspection form?

+The benefits of using a 90-day bit inspection form include ensuring regular and consistent inspections, providing a standardized format for recording inspection data, and facilitating communication between drillers, operators, and maintenance personnel.