As technology advances, the need for smaller, more efficient, and powerful computing systems becomes increasingly important. One of the key factors in achieving this is the development of standardized form factors for computer hardware. Among these, the 3U VPX form factor has gained significant attention in recent years due to its unique blend of compactness, performance, and versatility. In this article, we will delve into the world of 3U VPX form factor dimensions, exploring its specifications, benefits, and applications.

What is 3U VPX?

3U VPX, also known as 3U VITA 46, is a standardized form factor for embedded computing systems. It is part of the VITA (VME International Trade Association) standards, which aim to provide a common framework for designing and developing modular computing systems. The 3U VPX form factor is specifically designed for high-performance applications that require compact, rugged, and reliable systems.

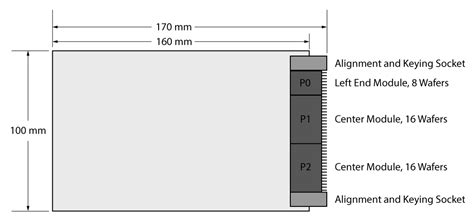

Dimensions and Specifications

The 3U VPX form factor is characterized by its compact dimensions, which are:

- Height: 3U (133.35 mm or 5.25 inches)

- Width: 160 mm (6.3 inches)

- Depth: 260 mm (10.2 inches)

In addition to its physical dimensions, the 3U VPX form factor also specifies various mechanical and electrical interfaces, such as:

- Backplane connectors: VPX connectors (VITA 46)

- Power supply: 12V, 24V, or 48V DC

- Cooling: Air-cooled or conduction-cooled

- Operating temperature: -40°C to +85°C (-40°F to +185°F)

Benefits of 3U VPX

The 3U VPX form factor offers several benefits that make it an attractive choice for various applications:

- Compactness: 3U VPX systems are designed to be compact and lightweight, making them ideal for applications where space and weight are limited.

- High performance: Despite its compact size, the 3U VPX form factor supports high-performance processing, making it suitable for demanding applications.

- Ruggedness: 3U VPX systems are designed to withstand harsh environments, including extreme temperatures, shock, and vibration.

- Flexibility: The 3U VPX form factor supports a wide range of applications, from military and aerospace to industrial and commercial.

Applications of 3U VPX

The 3U VPX form factor is used in various applications, including:

- Military and aerospace: 3U VPX systems are used in military and aerospace applications, such as radar, communication, and navigation systems.

- Industrial automation: 3U VPX systems are used in industrial automation applications, such as control systems, data acquisition, and process control.

- Medical devices: 3U VPX systems are used in medical devices, such as medical imaging, patient monitoring, and diagnostic equipment.

- Scientific research: 3U VPX systems are used in scientific research applications, such as data acquisition, simulation, and modeling.

Working Mechanisms

The 3U VPX form factor is based on a modular architecture, which allows for the integration of various modules and components. The working mechanisms of a 3U VPX system can be summarized as follows:

- Module integration: Modules are integrated into the system through the backplane connectors.

- Data communication: Data is communicated between modules through the VPX connectors.

- Power supply: The system is powered through the power supply connectors.

- Cooling: The system is cooled through air-cooling or conduction-cooling mechanisms.

Steps for Implementation

Implementing a 3U VPX system involves several steps:

- Define system requirements: Define the system requirements, including performance, power, and cooling needs.

- Select modules: Select the required modules, including processor, memory, and I/O modules.

- Integrate modules: Integrate the modules into the system through the backplane connectors.

- Configure software: Configure the software to manage data communication, power supply, and cooling.

- Test and validate: Test and validate the system to ensure it meets the required specifications.

Practical Examples

Here are some practical examples of 3U VPX systems:

- Radar system: A 3U VPX system can be used in a radar system to process and analyze radar signals in real-time.

- Medical imaging: A 3U VPX system can be used in medical imaging applications to process and analyze medical images.

- Industrial automation: A 3U VPX system can be used in industrial automation applications to control and monitor industrial processes.

Statistical Data

Here are some statistical data on the 3U VPX form factor:

- Market growth: The 3U VPX market is expected to grow at a CAGR of 10% from 2023 to 2028.

- Adoption rate: The adoption rate of 3U VPX systems is increasing rapidly, with over 50% of new systems being designed with 3U VPX form factor.

- Performance: 3U VPX systems can provide up to 100 Gbps of data transfer rate and 1000 GFLOPS of processing power.

Frequently Asked Questions

What is the maximum operating temperature of a 3U VPX system?

+The maximum operating temperature of a 3U VPX system is +85°C (+185°F).

What is the typical power consumption of a 3U VPX system?

+The typical power consumption of a 3U VPX system is around 100W to 200W.

Can 3U VPX systems be used in military applications?

+Yes, 3U VPX systems can be used in military applications, including radar, communication, and navigation systems.

Engage with Us

We hope this article has provided you with a comprehensive understanding of the 3U VPX form factor dimensions. If you have any questions or comments, please feel free to engage with us in the comments section below. We would love to hear from you and provide further insights into this topic.