In today's fast-paced business environment, efficient warehouse management is crucial for any company's success. With the rise of e-commerce and online shopping, the demand for swift and accurate order fulfillment has never been higher. To meet this demand, businesses need to have a well-organized and streamlined inventory management system in place. This is where a VFC (Vendor-Fulfilled Commerce) inventory form comes into play.

A VFC inventory form is a crucial tool for businesses that want to manage their inventory levels, track stock movements, and ensure that orders are fulfilled quickly and accurately. By implementing a VFC inventory form, businesses can streamline their warehouse management, reduce errors, and improve overall efficiency. In this article, we will explore the benefits of using a VFC inventory form, how it works, and provide practical examples of its implementation.

What is a VFC Inventory Form?

A VFC inventory form is a document used to track and manage inventory levels, stock movements, and order fulfillment in a warehouse or distribution center. It is typically used by vendors or suppliers who fulfill orders on behalf of their customers. The form provides a standardized way of recording and tracking inventory data, making it easier to manage stock levels, identify trends, and optimize inventory management processes.

Benefits of Using a VFC Inventory Form

Using a VFC inventory form can bring numerous benefits to a business, including:

- Improved inventory accuracy: By using a standardized form, businesses can reduce errors and ensure that inventory data is accurate and up-to-date.

- Increased efficiency: A VFC inventory form can help streamline inventory management processes, making it easier to track stock movements and fulfill orders quickly.

- Better inventory management: By tracking inventory levels and stock movements, businesses can optimize their inventory management processes, reducing stockouts and overstocking.

- Enhanced visibility: A VFC inventory form provides real-time visibility into inventory levels and stock movements, making it easier to identify trends and optimize inventory management processes.

How Does a VFC Inventory Form Work?

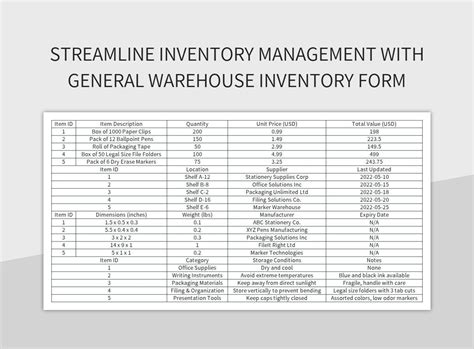

A VFC inventory form typically includes the following information:

- Inventory item details (e.g., product name, description, SKU)

- Quantity on hand

- Quantity allocated for orders

- Quantity available for sale

- Reorder point and reorder quantity

- Stock movement history

By tracking this information, businesses can quickly identify trends, optimize inventory levels, and ensure that orders are fulfilled quickly and accurately.

Practical Examples of VFC Inventory Form Implementation

Here are a few practical examples of how a VFC inventory form can be implemented in a business:

- E-commerce business: An e-commerce business can use a VFC inventory form to track inventory levels, fulfill orders, and optimize inventory management processes.

- Wholesale business: A wholesale business can use a VFC inventory form to track inventory levels, manage stock movements, and ensure that orders are fulfilled quickly and accurately.

- Distribution center: A distribution center can use a VFC inventory form to track inventory levels, manage stock movements, and optimize inventory management processes.

Best Practices for Implementing a VFC Inventory Form

Here are a few best practices for implementing a VFC inventory form:

- Use a standardized form: Use a standardized VFC inventory form to ensure that all inventory data is tracked and recorded consistently.

- Train staff: Train staff on how to use the VFC inventory form and ensure that they understand the importance of accurate inventory data.

- Monitor and adjust: Monitor inventory levels and adjust the VFC inventory form as needed to ensure that it is working effectively.

Common Challenges and Solutions

Here are a few common challenges and solutions related to implementing a VFC inventory form:

- Inaccurate inventory data: Use a standardized VFC inventory form and train staff to ensure that inventory data is accurate and up-to-date.

- Inventory discrepancies: Use a VFC inventory form to track inventory levels and identify discrepancies quickly.

- Inventory optimization: Use a VFC inventory form to optimize inventory management processes and reduce stockouts and overstocking.

Conclusion

In conclusion, a VFC inventory form is a crucial tool for businesses that want to streamline their warehouse management, reduce errors, and improve overall efficiency. By implementing a VFC inventory form, businesses can track inventory levels, manage stock movements, and optimize inventory management processes. Remember to use a standardized form, train staff, and monitor and adjust the form as needed to ensure that it is working effectively.

We hope this article has provided you with valuable insights into the benefits and implementation of a VFC inventory form. If you have any questions or comments, please don't hesitate to share them with us.

What is a VFC inventory form?

+A VFC inventory form is a document used to track and manage inventory levels, stock movements, and order fulfillment in a warehouse or distribution center.

How does a VFC inventory form work?

+A VFC inventory form typically includes information such as inventory item details, quantity on hand, quantity allocated for orders, quantity available for sale, reorder point and reorder quantity, and stock movement history.

What are the benefits of using a VFC inventory form?

+The benefits of using a VFC inventory form include improved inventory accuracy, increased efficiency, better inventory management, and enhanced visibility into inventory levels and stock movements.