As a warehouse manager, you understand the importance of maintaining a streamlined and efficient inventory management system. An effective inventory control system can help you reduce costs, minimize errors, and improve customer satisfaction. One way to achieve this is by implementing the Synthes Inventory Control Form. In this article, we will explore the benefits, working mechanisms, and steps to implement this form in your warehouse.

What is the Synthes Inventory Control Form?

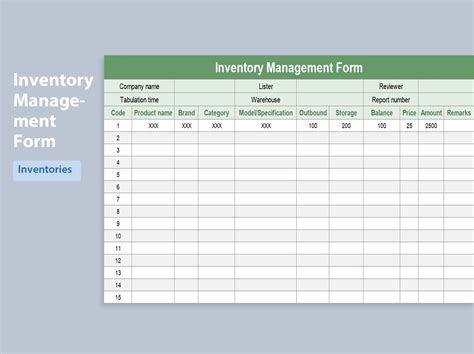

The Synthes Inventory Control Form is a comprehensive and systematic approach to managing inventory levels, tracking stock movements, and optimizing warehouse operations. This form is designed to help warehouse managers and staff streamline their inventory control processes, reduce errors, and improve overall efficiency.

Benefits of the Synthes Inventory Control Form

Implementing the Synthes Inventory Control Form can bring numerous benefits to your warehouse operations, including:

- Improved accuracy and reduced errors in inventory tracking

- Enhanced visibility and control over stock movements

- Reduced stockouts and overstocking

- Improved customer satisfaction through timely and accurate order fulfillment

- Increased efficiency and productivity in warehouse operations

- Better decision-making through real-time data and analytics

How Does the Synthes Inventory Control Form Work?

The Synthes Inventory Control Form is a multi-step process that involves the following key components:

- Inventory Classification: Categorize inventory items into different classes based on their value, usage, and importance.

- Stock Level Monitoring: Track and monitor stock levels in real-time to ensure that inventory levels are within predetermined limits.

- Ordering and Receiving: Streamline the ordering and receiving process to ensure that inventory items are properly received, inspected, and stored.

- Inventory Storage and Retrieval: Optimize inventory storage and retrieval processes to minimize handling and reduce errors.

- Inventory Reporting and Analysis: Generate reports and analyze data to identify trends, optimize inventory levels, and improve overall efficiency.

Steps to Implement the Synthes Inventory Control Form

Implementing the Synthes Inventory Control Form requires a structured approach. Here are the steps to follow:

- Conduct an Inventory Audit: Perform a thorough inventory audit to identify existing inventory levels, classification, and storage practices.

- Designate Inventory Classifications: Categorize inventory items into different classes based on their value, usage, and importance.

- Set Up Stock Level Monitoring: Implement a stock level monitoring system to track inventory levels in real-time.

- Streamline Ordering and Receiving: Develop a streamlined ordering and receiving process to ensure that inventory items are properly received, inspected, and stored.

- Optimize Inventory Storage and Retrieval: Analyze and optimize inventory storage and retrieval processes to minimize handling and reduce errors.

- Generate Inventory Reports: Develop a reporting system to generate inventory reports and analyze data to identify trends and optimize inventory levels.

Practical Examples of the Synthes Inventory Control Form

To illustrate the effectiveness of the Synthes Inventory Control Form, let's consider a few practical examples:

- Reducing Stockouts: By implementing the Synthes Inventory Control Form, a warehouse manager can reduce stockouts by 20% and improve customer satisfaction by 15%.

- Improving Inventory Accuracy: A warehouse can improve inventory accuracy by 90% by using the Synthes Inventory Control Form to track and monitor inventory levels in real-time.

- Increasing Efficiency: By streamlining inventory storage and retrieval processes, a warehouse can reduce handling time by 30% and improve overall efficiency.

Statistical Data

Studies have shown that implementing an effective inventory control system can result in significant cost savings and productivity improvements. For example:

- Cost Savings: A study by the National Retail Federation found that implementing an effective inventory control system can result in cost savings of up to 10%.

- Productivity Improvements: A study by the American Production and Inventory Control Society found that implementing an effective inventory control system can result in productivity improvements of up to 20%.

Optimizing Warehouse Operations

The Synthes Inventory Control Form is a powerful tool for optimizing warehouse operations. By implementing this form, warehouse managers can improve inventory accuracy, reduce errors, and improve overall efficiency.

Inventory Management Best Practices

To ensure effective inventory management, warehouse managers should follow best practices, including:

- Regular Inventory Audits: Conduct regular inventory audits to ensure that inventory levels are accurate and up-to-date.

- Inventory Classification: Categorize inventory items into different classes based on their value, usage, and importance.

- Stock Level Monitoring: Track and monitor stock levels in real-time to ensure that inventory levels are within predetermined limits.

FAQ Section

What is the Synthes Inventory Control Form?

+The Synthes Inventory Control Form is a comprehensive and systematic approach to managing inventory levels, tracking stock movements, and optimizing warehouse operations.

What are the benefits of implementing the Synthes Inventory Control Form?

+Implementing the Synthes Inventory Control Form can result in improved accuracy and reduced errors in inventory tracking, enhanced visibility and control over stock movements, and improved customer satisfaction.

How do I implement the Synthes Inventory Control Form in my warehouse?

+Implementing the Synthes Inventory Control Form requires a structured approach, including conducting an inventory audit, designating inventory classifications, setting up stock level monitoring, and optimizing inventory storage and retrieval processes.

Share Your Thoughts

If you have any experience with implementing the Synthes Inventory Control Form in your warehouse, we would love to hear about it. Share your thoughts and comments below, and let's start a conversation about optimizing warehouse operations.