Welding is a crucial process in various industries, including construction, manufacturing, and oil and gas. The American Welding Society (AWS) plays a vital role in promoting welding excellence and safety through its certification programs, including the AWS Welder Qualification Form. This article will delve into the requirements and guidelines for the AWS Welder Qualification Form, providing valuable insights for welders, employers, and inspection agencies.

Importance of AWS Welder Qualification

The AWS Welder Qualification Form is a critical document that verifies a welder's competence to perform specific welding tasks. The qualification process ensures that welders have the necessary skills, knowledge, and experience to produce high-quality welds that meet industry standards. By qualifying welders, employers can ensure that their workforce is capable of producing safe and reliable welds, reducing the risk of accidents and costly repairs.

AWS Welder Qualification Form Requirements

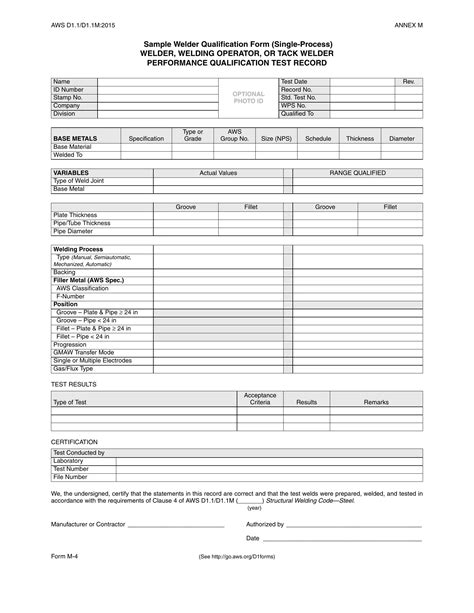

To qualify as an AWS-certified welder, individuals must meet specific requirements and guidelines outlined in the AWS Welder Qualification Form. The form is divided into several sections, each addressing a critical aspect of the qualification process.

Section 1: Welder Information

This section requires the welder to provide personal and contact information, including their name, address, phone number, and email address.

Welder's Name and Address

The welder's name and address must be accurately recorded, as this information will be used to identify the qualified welder.

Contact Information

The welder's contact information, including phone number and email address, must be provided to facilitate communication with the employer, inspection agency, or AWS.

Section 2: Welding Process and Position

This section requires the welder to specify the welding process and position they are qualified to perform.

Welding Process

The welder must select the welding process they are qualified to perform, such as Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), or Flux Cored Arc Welding (FCAW).

Welding Position

The welder must also specify the welding position they are qualified to perform, such as flat, horizontal, vertical, or overhead.

Section 3: Welding Procedure Specification (WPS)

This section requires the welder to provide information about the Welding Procedure Specification (WPS) they are qualified to follow.

WPS Number and Revision

The welder must provide the WPS number and revision they are qualified to follow.

WPS Description

The welder must provide a brief description of the WPS, including the welding process, joint design, and materials.

Section 4: Qualification Tests

This section requires the welder to provide information about the qualification tests they have passed.

Test Method and Results

The welder must specify the test method used, such as visual inspection, radiography, or bend testing, and provide the test results.

Test Date and Location

The welder must provide the date and location of the qualification test.

Section 5: Qualification Verification

This section requires the employer or inspection agency to verify the welder's qualification.

Verification Statement

The employer or inspection agency must provide a statement verifying the welder's qualification, including the date and location of the verification.

Verification Signature

The employer or inspection agency must sign and date the verification statement.

Guidelines for Completing the AWS Welder Qualification Form

To ensure accuracy and completeness, the following guidelines should be followed when completing the AWS Welder Qualification Form:

- The form must be completed in its entirety, with all sections filled out accurately and thoroughly.

- The form must be signed and dated by the welder, employer, and inspection agency, as applicable.

- The form must be maintained by the employer or inspection agency for a minimum of three years.

- The form must be available for inspection by AWS or other authorized personnel.

Benefits of AWS Welder Qualification

The AWS Welder Qualification Form provides numerous benefits to welders, employers, and inspection agencies, including:

- Improved Safety: By verifying a welder's competence, the AWS Welder Qualification Form helps ensure that welds are safe and reliable, reducing the risk of accidents and injuries.

- Increased Efficiency: The qualification process helps employers identify qualified welders, reducing the time and cost associated with training and testing.

- Enhanced Quality: The AWS Welder Qualification Form helps ensure that welds meet industry standards, improving the overall quality of the welding process.

Conclusion

The AWS Welder Qualification Form is a critical document that verifies a welder's competence to perform specific welding tasks. By following the requirements and guidelines outlined in this article, welders, employers, and inspection agencies can ensure that the qualification process is completed accurately and thoroughly. The benefits of AWS Welder Qualification are numerous, including improved safety, increased efficiency, and enhanced quality.

FAQ Section

What is the purpose of the AWS Welder Qualification Form?

+The AWS Welder Qualification Form verifies a welder's competence to perform specific welding tasks, ensuring that welds are safe and reliable.

Who is responsible for completing the AWS Welder Qualification Form?

+The welder, employer, and inspection agency are responsible for completing the AWS Welder Qualification Form, as applicable.

How long must the AWS Welder Qualification Form be maintained?

+The AWS Welder Qualification Form must be maintained by the employer or inspection agency for a minimum of three years.